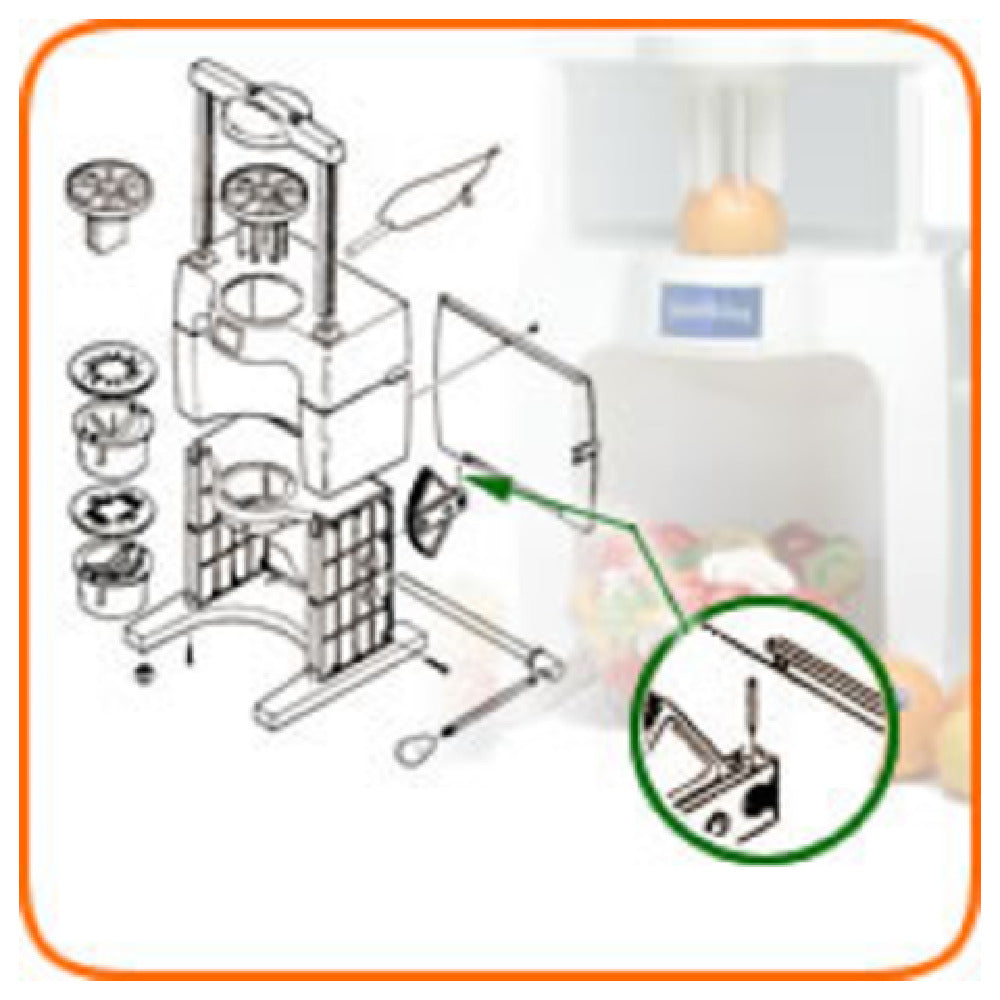

Sunkist S-14K Spring Pin Set of 2 for Fruit Vegetable Wedger Parts

Delivery to:

- Corrosion-resistant stainless steel construction ensures longevity

- Supports high-volume processing with reliable fastening

- Quick installation reduces equipment downtime

- View More Details

Best Price Guarantee

Best Price Guarantee

Secure Shopping

Secure Shopping

The Sunkist S-14K Spring Pin is a precision-engineered component designed for commercial food processing equipment, specifically as a vital part of fruit and vegetable wedger assemblies. Manufactured by Sunkist, this spring pin features robust construction with corrosion-resistant materials, ensuring durability in demanding kitchen environments. It is crafted to facilitate secure fastening and smooth operation within wedger mechanisms, supporting efficient slicing and portioning tasks. The model number S-14K denotes its specific dimensions and compatibility, making it suitable for high-volume processing lines requiring reliable component performance. The set includes two spring pins, optimized for quick installation and maintenance in professional culinary settings.

Designed for industrial fruit and vegetable processing, the S-14K spring pin delivers precise fastening with high tensile strength. Its stainless steel construction ensures long-lasting performance even in wash-down environments, reducing downtime. This set supports easy installation and replacement, minimizing workflow disruptions during maintenance. Ideal for assembly line assembly in commercial kitchens, its compact design ensures compatibility with various wedger models, improving overall efficiency. The inclusion of two pins allows for streamlined maintenance routines and extended equipment uptime.

Ideal for replacement in high-volume produce processing lines requiring dependable component support.

The Sunkist S-14K spring pin features a stainless steel construction, with an approximate weight of 2.32 lbs for the set of two units. It is compatible with various wedger models that demand precise fastening components. The pin’s dimensions adhere to manufacturer specifications for optimal fit, ensuring seamless integration into existing equipment. It does not specify electrical requirements or cooling methods, being a mechanical fastening part. The stainless steel material offers excellent resistance to corrosion and wear, suitable for food processing environments where frequent cleaning is necessary. The pins are designed for straightforward installation with dimensions tailored for specific wedger assemblies, contributing to quick maintenance cycles and reduced downtime.

A commercial spring pin is a precision fastener used in industrial kitchen equipment to reliably secure parts such as wedger blades and components. Crafted from corrosion-resistant metals like stainless steel, these pins facilitate quick assembly and maintenance of produce processing machinery, supporting high-volume workflows. The S-14K model by Sunkist, specifically, is designed to fit within fruit and vegetable wedger assemblies, providing durability and operational stability. These pins are critical in maintaining equipment integrity and ensuring consistent slicing performance in commercial foodservice operations, including high-demand processing lines and food production facilities.

This precision fastener is ideal for moderate throughput commercial kitchens and food processing facilities requiring reliable securing components in produce wedgers. Manufactured by Sunkist, the S-14K spring pin supports efficient assembly and maintenance, ensuring optimal performance for high-volume slicing operations. Its robust stainless steel design makes it suitable for food-safe environments, contributing to streamlined workflows in industrial produce processing and catering outlets.

The Sunkist S-14K spring pin distinguishes itself with its stainless steel construction designed for durability, corrosion resistance, and reliable performance in demanding foodservice environments. Its precise manufacturing ensures secure fastening within wedger assemblies, minimizing operational disruptions. Compared to standard components, it offers superior longevity, ease of replacement, and compatibility with existing equipment, contributing to overall operational efficiency and sanitation standards in professional food processing.