Omcan 20367 22 Inch Floor Model Electric Potato Peeler Stainless Steel 55 Lb Capacity

Delivery to:

- Footprint supports high-volume processing

- 55 lb capacity maximizes throughput

- 1HP motor ensures consistent power

- View More Details

Best Price Guarantee

Best Price Guarantee

Secure Shopping

Secure Shopping

The Omcan 20367 (PE-BR-0025) Elite Series Potato Peeler is a commercial-grade electric food processing device designed for high-efficiency peeling operations. With a robust stainless steel construction and a 55-pound capacity, this floor model is tailored for industrial kitchens, produce processing facilities, and large-scale foodservice environments. Its integrated safety sensor and sealed electrical components ensure safe, reliable operation, while the 1HP motor provides consistent performance in demanding workflows. This model optimally supports continuous peeling tasks, reducing manual labor and increasing throughput in high-volume production lines.

This commercial potato peeler features a durable stainless steel build, protected electrical components, and a safety sensor for reliable operation. It handles up to 55 lbs of produce per batch, ideal for large-scale peeling tasks. Its floor-mounted design ensures stability during continuous use, and maintenance is simplified with accessible components. Suitable for industrial kitchens and produce processing facilities, it seamlessly integrates into high-volume workflows to improve efficiency and productivity.

Ideal for large produce preparation operations requiring efficient peeling solutions

The Omcan 20367 (PE-BR-0025) Elite Series Potato Peeler operates on 110V/60Hz single-phase power with a 1HP motor, ensuring sufficient power for continuous peeling tasks. Its construction utilizes durable stainless steel, with overall dimensions of 22 inches in width, 26 inches in depth, and 45.5 inches in height, and a weight of 141 lbs. The self-contained design incorporates sealed electrical systems and safety features like a sensor to protect operators. Designed for high-volume daily use, it handles production capacities of 55 lbs per batch, with straightforward access for cleaning and maintenance. No refrigeration or cooling system is required, reflecting its efficient air-cooled operation tailored for industrial kitchen environments. It supports safety and sanitation standards with a resilient build and user-friendly features for reliable operation in busy food processing settings.

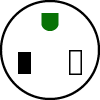

Electrical connection: 110V, 60Hz, single-phase, 5-15P plug

Material: Robust stainless steel for longevity and sanitation

Operating environment: Suitable for dry, clean industrial kitchens and produce processing lines

Output type: Large batch capacity optimized for continuous peeling

Maintenance needs: Accessible electrical components and corrosion-resistant surfaces

A commercial potato peeler is a specialized food processing device used in high-volume kitchens and produce handling facilities to rapidly peel large quantities of potatoes and other root vegetables. Designed for durability and efficiency, these machines typically feature stainless steel construction, sealed electrical components, and safety sensors. The Omcan 20367 (PE-BR-0025) Elite Series is engineered for industrial use, with a capacity of 55 pounds per batch, making it suitable for large-scale foodservice operations such as catering, institutional kitchens, and produce processing plants. Its robust motor and safety features support continuous operation, ensuring productivity and uniform peeling performance essential for high-demand food processing environments.

Designed for industrial kitchens and large-scale produce processing, the Omcan 20367 (PE-BR-0025) delivers reliable, efficient peeling operation with a build quality suited for moderate workloads. Omcan’s model is commercially engineered for durability, safety, and consistent output, making it ideal for high-volume peeling tasks in busy foodservice environments.

Compared to other commercial peelers, this Omcan model offers a robust stainless steel build with protected electrical components and a safety sensor, enhancing durability and operator safety. Its high-capacity design and 1HP motor streamline peeling workflows, reducing manual labor and boosting productivity. The floor-standing configuration and easy maintenance features make it a practical choice for demanding food processing environments seeking reliability and performance.

Product Description

Certifications

Certifications

5-15P

This unit is equipped with a NEMA 5-15P plug.

From the manufacturer