Legion DCS41-7 31.2-gallon Direct Steam Tilting Skillet Stainless Steel with Adjustable Steam Vent

Delivery to:

- Footprint & configuration enable large capacity.

- 31.2-gallon capacity supports high-volume cooking.

- Stainless steel construction ensures durability.

- View More Details

Best Price Guarantee

Best Price Guarantee

Secure Shopping

Secure Shopping

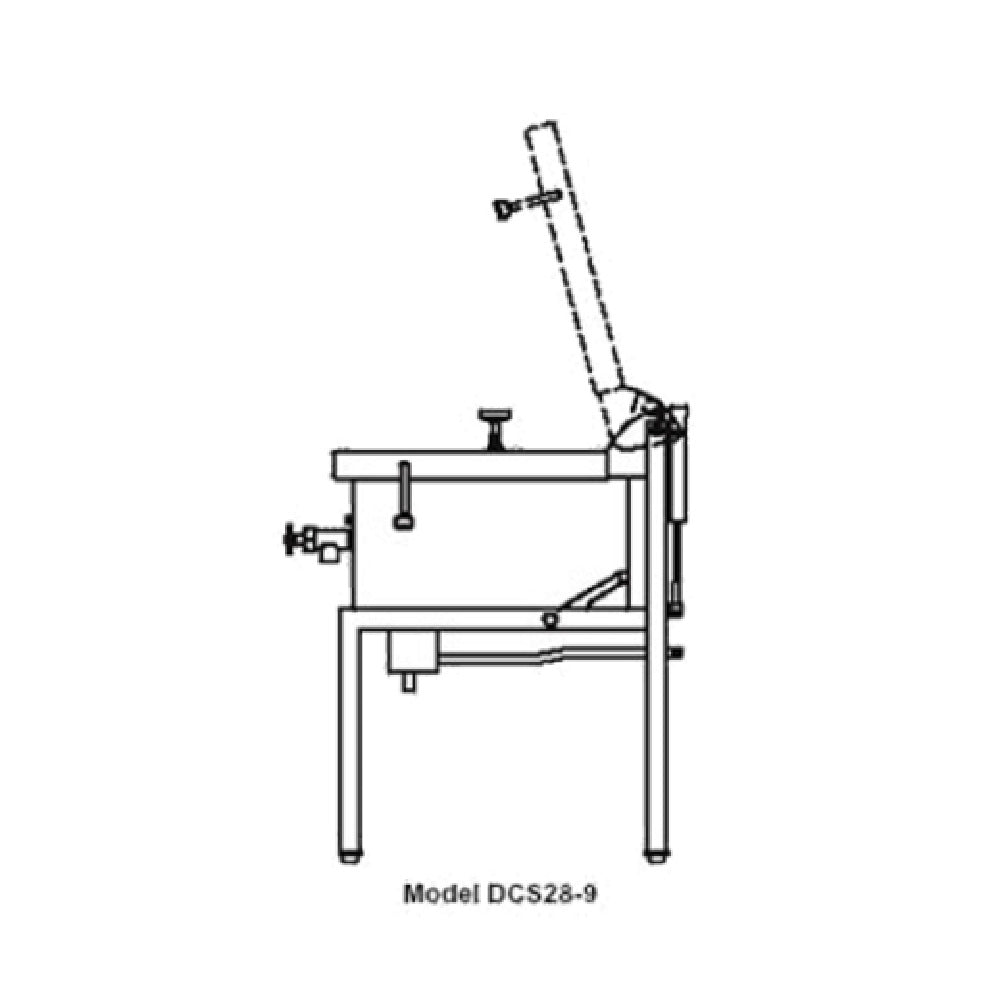

The Legion DCS41-7 Combi-Pan Tilting Skillet with Direct Steam is a commercial-grade cooking appliance designed for high-capacity foodservice operations. With a 31.2-gallon capacity, it features a precisely engineered 10° tilting pan for efficient food transfer, an adjustable steam vent for precise humidity control, and a 1-1/2" draw-off valve for streamlined drainage. Constructed from durable stainless steel with an open frame and flanged front and bullet back feet, this unit offers robust performance and ease of maintenance ideal for large-scale kitchens, cafeterias, and institutional facilities seeking reliable, high-volume cooking solutions.

The Legion DCS41-7 Combi-Pan Tilting Skillet is optimized for medium-volume cooking environments requiring durable, high-capacity equipment. Its stainless steel construction ensures longevity under demanding conditions, while the 10° tilting pan facilitates ergonomic handling and efficient food discharge. The adjustable steam vent allows operators to fine-tune humidity levels during operation, and the open frame design simplifies cleaning routines. Designed for benchtop or stand-mounted installation, it integrates seamlessly into high-performance foodservice workflows, supporting consistent, high-quality results in busy kitchens.

Ideal for institutional kitchens, large catering facilities, or central cooking stations requiring reliable high-volume braising.

The Legion DCS41-7 Tilting Skillet Braising Pan operates with a self-contained steam system, utilizing direct steam input to maintain consistent cooking temperatures. Crafted from high-grade stainless steel, the unit measures approximately 54.5 inches wide, 30 inches deep, and 20 inches high. It weighs 545 lbs, ensuring stability during operation. The pan's construction features a durable, corrosion-resistant metal gauge suitable for demanding commercial environments. Operating temperatures are designed to sustain precise heat ranges suitable for braising, simmering, and large batch cooking. With a freight class of 85 and typically shipping within 1 to 2 days, this equipment is suited for installation on stable, level surfaces with necessary drainage and ventilation considerations. The unit's design emphasizes food safety, with easy-to-clean surfaces and components compatible with standard commercial cleaning practices.

Installation should account for adequate clearance for tilting, steam venting, and drainage; ensure level mounting surface and proper ventilation for optimal performance.

A commercial tilting skillet braising pan is a versatile cooking appliance used for large-scale food preparation in high-volume kitchens. It combines the functions of a skillet and braising pan, featuring a tilting mechanism for easy transfer of contents and direct steam or other heating methods for uniform cooking. The Legion DCS41-7 model, with its 31.2-gallon capacity and durable stainless steel construction, is installed in institutional kitchens, cafeterias, or catering operations requiring efficient, consistent, and scalable cooking solutions ideal for braising, simmering, and mixed food preparations in busy foodservice environments.

This high-capacity commercial tilting skillet, Legion DCS41-7, offers robust construction, precise control, and reliable performance, making it ideal for large-scale kitchens. Designed for medium-volume throughput, it supports efficient food production in institutional, catering, and central kitchen settings.

Legion DCS41-7 distinguishes itself through its durable stainless steel design, high-capacity tilting pan, and enhanced usability, providing a reliable solution for demanding foodservice applications. Its precise steam control and open-frame build streamline operation and maintenance, supporting efficient workflows while maintaining food safety standards. Its robust construction and thoughtful design enhance operational efficiency compared to other models in this class.