Legion DCS41-5 22.3 Gallon Direct Steam Tilting Skillet with Adjustable Vent

Delivery to:

- High-capacity 22.3-gallon stainless steel construction

- Precise pressure control with adjustable vent

- Robust design supports continuous high-volume use

- View More Details

Best Price Guarantee

Best Price Guarantee

Secure Shopping

Secure Shopping

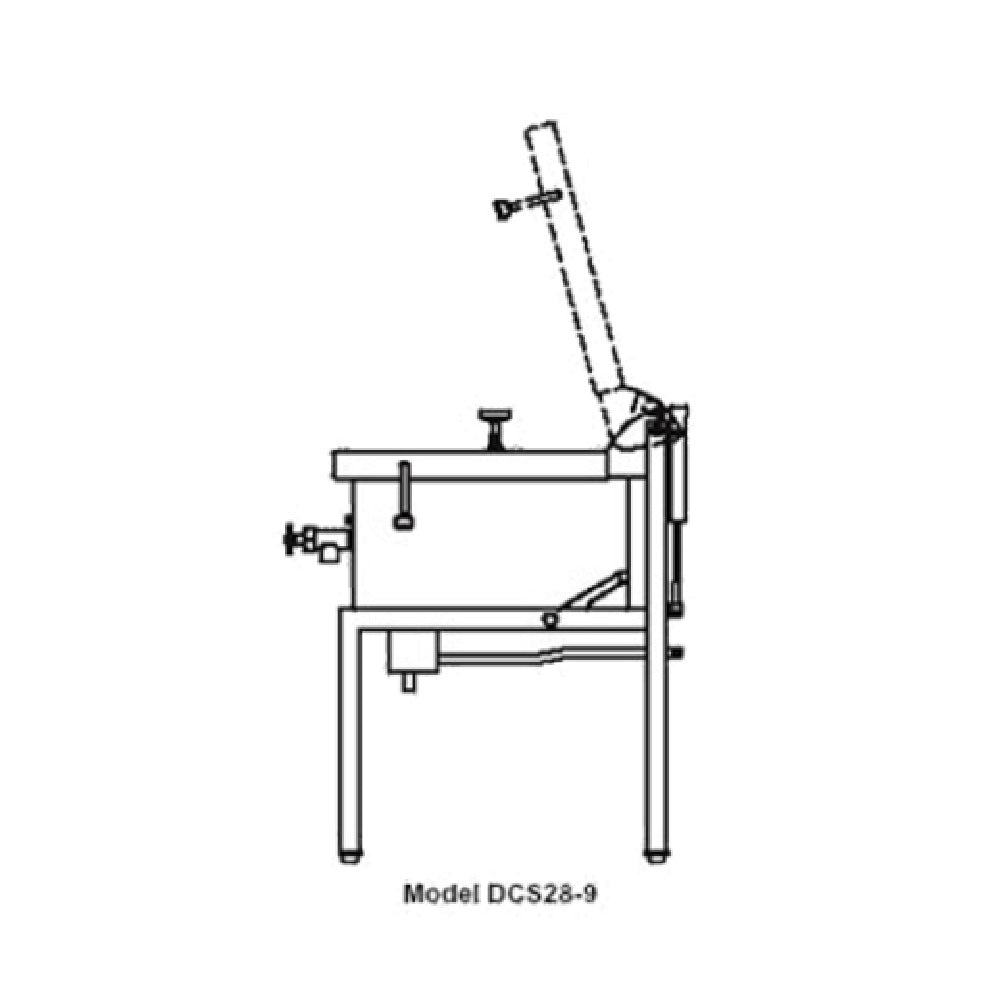

The Legion DCS41-5 Combi-Pan Tilting Skillet with Direct Steam technology is a commercial-grade braising pan designed for precise, high-capacity cooking in professional kitchens. This 22.3-gallon tilting skillet features a durable stainless steel construction with an open frame design for optimal heat distribution and ease of cleaning. Equipped with a 10° tilting pan for efficient product removal, an adjustable steam vent for pressure regulation, and a 1-1/2" draw-off valve for streamlined drainage, it provides reliable performance for high-volume foodservice operations. Its stainless steel lid with actuator-assisted counterbalance ensures safe, effortless handling during operation, making it suitable for continuous use in busy restaurant, cafeteria, or institutional kitchens. The model number DCS41-5 offers precise control over steam and tilt functionality, essential for consistent, high-quality cooking results.

The Legion DCS41-5 tilting skillet combines a 22.3-gallon capacity with high durability stainless steel construction, enabling versatile braising, sautéing, and simmering. Its adjustable steam vent allows fine pressure control, while the open frame facilitates quick cleaning and maintenance. Designed for mid-volume cooking workflows, it supports a 10° tilting mechanism for efficient product transfer. The stainless steel lid with actuator-assisted balance enhances safety and ease of operation in demanding kitchen environments.

Ideal for high-volume food production in restaurant or institutional kitchens requiring reliable capacity and performance.

The Legion DCS41-5 tilting skillet features a sturdy stainless steel construction, with a product weight of 512 lbs and a freight class of 85. It operates with direct steam input, providing efficient heat transfer without the need for external electrical connections. The unit is compatible with typical kitchen plumbing for steam and drainage, with safety features supporting maximum operating ranges up to 600°F. Its dimensions support installation in space-constrained environments, measuring in width, depth, and height, optimized for easy integration into existing cooking stations. Maintenance includes disassembly of the stainless steel lid with actuator-assisted counterbalance, ensuring longevity and ease of cleaning. For safety and operational efficiency, it is built with flanged front feet and bullet back feet for stable placement.

A commercial tilting skillet braising pan is a versatile piece of kitchen equipment designed for high-volume cooking, combining braising, sautéing, boiling, and steaming functions in a single unit. Specifically, the Legion DCS41-5 model features a 22.3-gallon capacity, stainless steel construction for durability, and direct steam heating for efficient energy use. Installed in restaurant, cafeteria, or institutional kitchens, this equipment supports consistent, high-pressure cooking with easy tilt and drain features. It is ideal for preparing large quantities of soups, stews, pasta, or braised dishes, ensuring rapid service in moderate to high-volume foodservice settings.

Designed for moderate throughput in busy restaurant kitchens, the Legion DCS41-5 combines durable stainless steel build with precise tilt and steam control, supporting large batch cooking and serving. Legion DCS41-5 excels in institutional and commercial kitchens for consistent, reliable performance with a compact footprint suitable for tight spaces.

Legion DCS41-5 stands out among commercial tilting skillets with its heavy-duty stainless steel construction, precise steam and tilt control, and user-friendly features like the actuator-assisted lid and open frame for easy cleaning. Its robust design ensures long-term durability and reliable performance, improving operational efficiency and safety in demanding culinary environments.