Dynamic TB012 11 Inch Diameter Mixer Attachment for Up to 400 Liters Stainless Steel

Delivery to:

- Footprint & Configuration: Stainless steel construction ensures durability.

- Capacity & Throughput: Supports mixing of up to 400 liters efficiently.

- Core Performance Specs: RPM range of 2800 to 4000 ensures versatile blending.

- View More Details

Best Price Guarantee

Best Price Guarantee

Secure Shopping

Secure Shopping

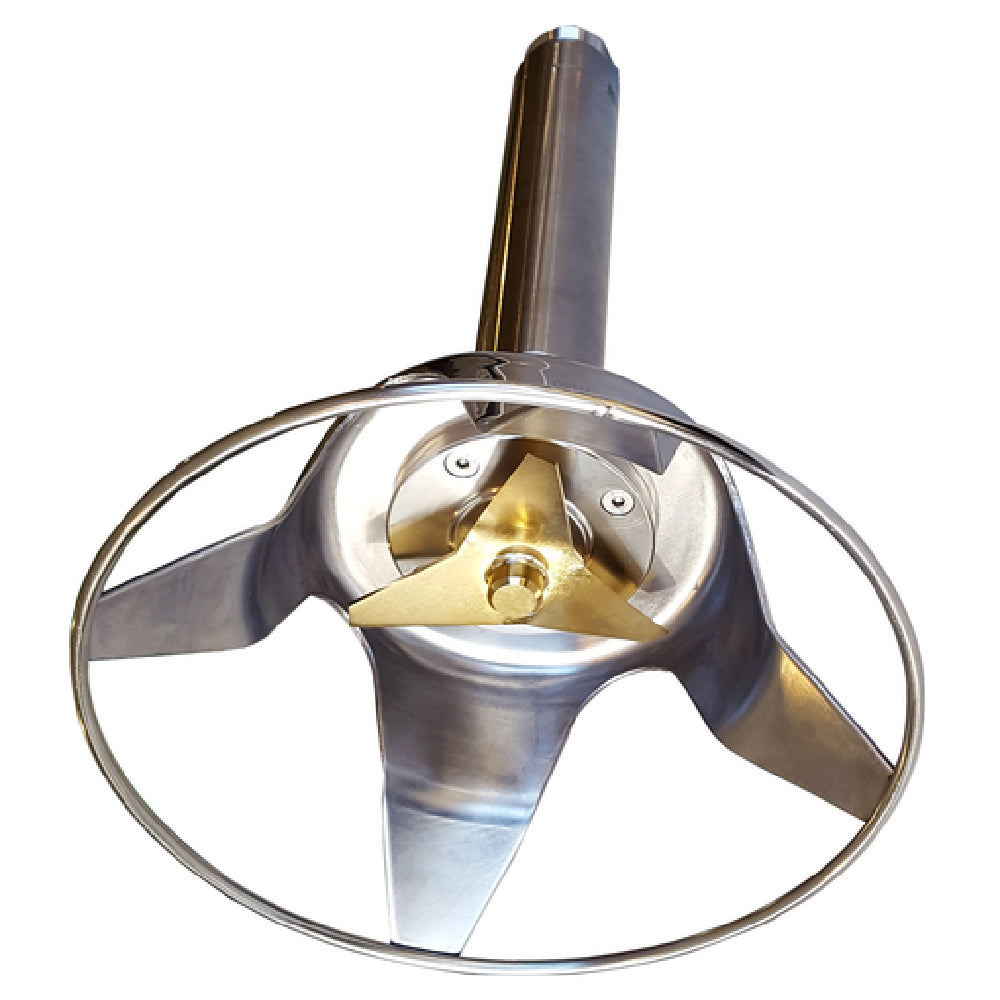

The Dynamic TB012 Power Pro Mixer Tool Attachment is a commercial-grade stainless steel mixing accessory designed for high-volume food processing environments. With an 11-inch diameter and 6-1/2-inch height, this mixer attachment is engineered to optimize blending and mixing tasks for up to 400 liters of product, operating smoothly within a speed range of 2800 to 4000 RPM. Its robust construction and precise dimensions make it suitable for industrial kitchens, food manufacturing, and large-scale catering operations requiring reliable performance and consistent results.

The TB012 mixer attachment offers high-performance mixing with a stainless steel build for durability and ease of maintenance. Its 11-inch diameter blade ensures thorough blending of large batches, while the RPM range provides flexible control for different ingredients. Designed for commercial foodservice use, it integrates seamlessly with mixer units, supporting workflows that demand robustness and efficiency. Its corrosion-resistant construction and straightforward cleaning make it suitable for frequent use in demanding kitchen environments.

Ideal for large-scale mixing tasks in food manufacturing or industrial kitchens

The TB012 mixer attachment from Dynamic USA features a stainless steel construction for resilience in heavy-duty environments. Its dimensions include an 11-inch blade diameter and a height of 6-1/2 inches, suitable for large batch processing. It operates within a speed range of 2800 to 4000 RPM, facilitating precise control over mixing intensity. The unit is designed for compatibility with industry-standard commercial mixers, supporting capacities of up to 400 liters. With a freight class of 85, it ensures reliable shipment, and the product is built to handle consistent use in demanding commercial settings. Its construction adheres to high food safety standards, with straightforward cleaning and maintenance routines. Dimensions are tailored for easy integration into existing kitchen or production line layouts, and its stainless steel finish maintains hygiene and corrosion resistance. The unit's weight and engineering specifications ensure stability during operation, making it a reliable tool for large-volume food processing.

A commercial mixer attachment is a stainless steel accessory designed to expand the functionality of industrial or restaurant-grade mixers. It typically features durable construction to withstand frequent use in high-volume foodservice environments, with dimensions optimized for large batch processing. The TB012 model from Dynamic USA is installed in commercial mixers to enhance mixing efficiency for applications such as bulk ingredient blending, batter preparation, or food processing. It is particularly suitable for large-scale kitchens, food production plants, and catering facilities needing reliable, high-capacity mixing solutions to support operational throughput in industrial foodservice settings.

Designed for medium to large kitchens, the TB012 mixing attachment from Dynamic USA provides reliable high-capacity blending with a durable stainless steel build and 11-inch blade diameter, optimized for up to 400 liters. It supports continuous operation in busy commercial kitchens, ideal for food manufacturing or large catering services requiring consistent mixing performance.

Compared to similar mixer attachments, the TB012 emphasizes substantial capacity, stainless steel durability, and precise RPM control for consistent results. Its robust construction ensures longevity in demanding environments, while its compatibility with a variety of mixers streamlines large-batch workflows. This model enhances operational efficiency, sanitation, and workload management, making it a reliable choice for high-volume food processing facilities.

Product Description

From the manufacturer