Arcobaleno Pasta Equipment FLRDUST-ADC160 Flour Duster for ADC160

Delivery to:

- Precisely controls flour dusting in high-volume lines

- Constructed from corrosion-resistant stainless steel

- Operates manually without electrical power

- View More Details

Special Quote Item.

Best Price Guarantee

Best Price Guarantee

Secure Shopping

Secure Shopping

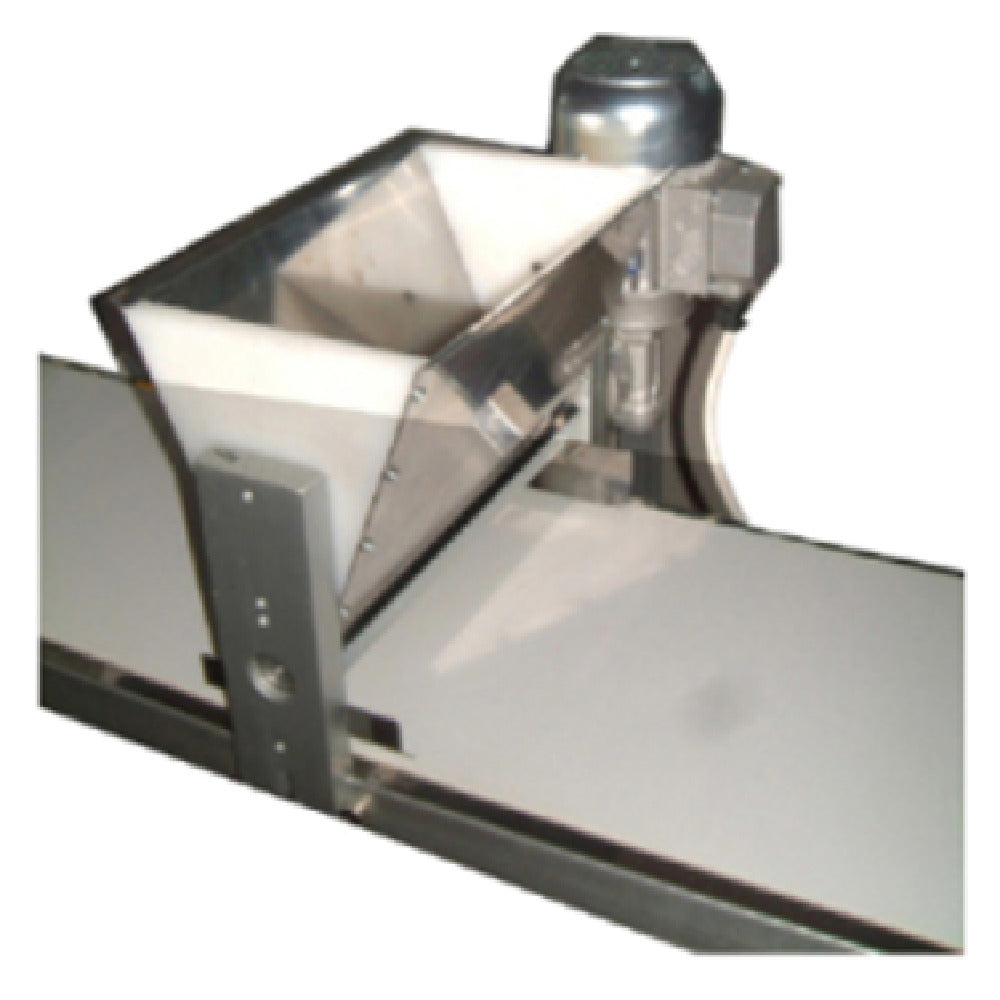

The Arcobaleno Pasta Equipment FLRDUST-ADC160 Flour Duster is a commercial-grade accessory designed specifically for the ADC160 pasta production line. Constructed from high-quality materials, it provides precise flour application to streamline pasta production workflows. Its robust construction ensures durability under heavy daily use, and its compatibility with the ADC160 model enhances consistency in dough preparation. This foodservice accessory is essential for manufacturers seeking efficient flour dusting solutions with accurate dispersion capabilities, featuring an adjustable nozzle for uniform coating and a stainless steel body for longevity.

Designed for commercial pasta production, the Arcobaleno FLRDUST-ADC160 flour duster offers precise control and durable construction suited for high-volume kitchens. Its hand-operated mechanism allows for consistent flour distribution while its stainless steel body ensures resistance to wear and corrosion. The duster’s ergonomic design facilitates quick loading and cleaning, making it ideal for continuous workflow in busy pasta manufacturing environments with precise dusting needs.

Ideal for commercial pasta production facilities requiring precise flour dusting at high throughput levels.

The Arcobaleno FLRDUST-ADC160 flour duster operates as a reliable, manually controlled accessory with a stainless steel construction measuring approximately 10 inches in width, 8 inches in depth, and 12 inches in height. Its durable steel body withstands demanding bakery environments, while the ergonomic handle allows for controlled flour application. The unit does not require electrical power, simplifying installation and maintenance. Its compatibility with ADC160 pasta machine models makes it an integral part of pasta production lines, especially suited for medium-volume operations. With an emphasis on sanitation, the materials used are compatible with standard cleaning routines, and the device’s design promotes efficient workflow, reducing flour waste and ensuring uniform dusting throughout the process.

Electrical Compatibility: No electrical connection required

Installation & Clearance: Fits easily onto ADC160 unit with minimal space; requires surface clearance for operation

Material Safety: Food-grade stainless steel, compatible with standard cleaning chemicals

Operational Setup: Hand-loaded flour hopper with adjustable nozzle for precise dusting

Maintenance Needs: Lubrication and disassembly for periodic cleaning

A commercial flour duster is a specialized device used in high-volume food production settings to evenly distribute flour or similar powders onto dough or surfaces. Designed for durability and precision, it typically features a stainless steel body and controlled dusting mechanisms. The Arcobaleno Pasta Equipment FLRDUST-ADC160 flour duster is optimized for use with ADC160 pasta machines, enabling efficient flour application in pasta processing. It is installed directly onto production lines and helps ensure consistent dough quality in medium-volume foodservice establishments, such as pasta factories or industrial kitchens focused on large-scale output.

Built with high-quality materials, the Arcobaleno FLRDUST-ADC160 offers precise dusting function and durability for medium-volume pasta manufacturing operations. It is designed for integration with ADC160 models, ideal for efficient workflows in commercial kitchens and pasta facilities. This model supports consistent flour application, supporting high-quality, restaurant-ready pasta outputs in busy environments.

Arcobaleno Pasta Equipment FLRDUST-ADC160 stands out with its robust stainless steel construction and precise manual dusting capability, designed specifically for ADC160 pasta lines. Its tray system and adjustable nozzle enhance dusting accuracy and workflow efficiency, reducing flour waste and promoting consistent product quality. The durable design and straightforward maintenance make it superior to common dusters, supporting reliable operation in demanding commercial kitchens and pasta manufacturing facilities.