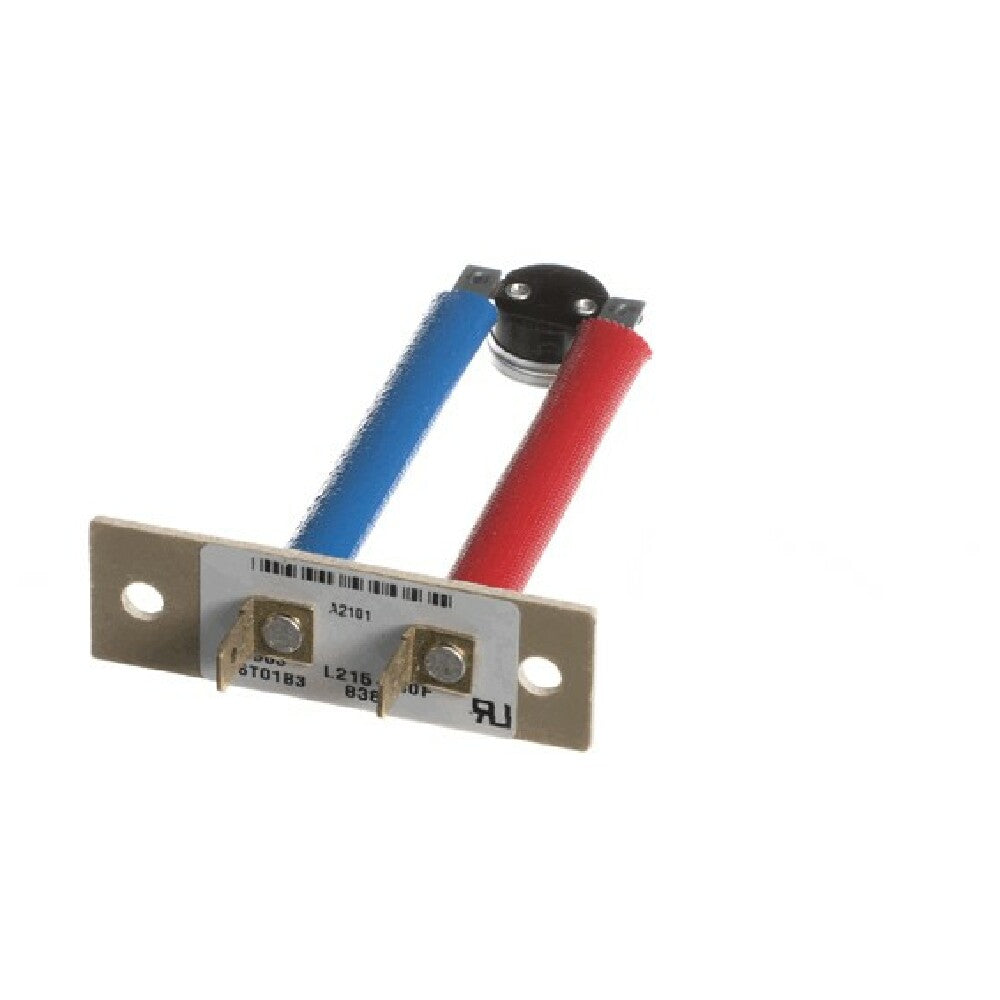

AllPoints S1-02537344000 Limit Switch 6.1 Inch Corrosion Resistant with Sealed Design

Delivery to:

- Corrosion-resistant stainless steel contact points

- Compact 6.1-inch wide OEM design fits easily

- Sealed contacts support washdown environments

- View More Details

Best Price Guarantee

Best Price Guarantee

Secure Shopping

Secure Shopping

The York S1-02537344000 Limit Switch 215/185(o/c) Aut is a commercial limit switch designed for precise control in industrial and food processing machinery. Built by York, a recognized leader in industrial automation components, this OEM device features a robust electrical design suitable for applications requiring reliable, contact-based operation. Its core function is to detect physical boundaries within equipment to ensure safety and performance, making it an essential component in conveyor systems, packaging machinery, and automated food processing lines. With its high-accuracy contact mechanism, the limit switch provides consistent switching functions critical for maintaining operational workflow in commercial kitchens and manufacturing environments.

The Limit Switch 215/185(o/c) Aut features a compact, durable construction with sealed contacts for washdown and sanitation environments. Engineered for manual operation with easy installation, it fits standard mounting brackets and supports automation workflows. Its high-reliability contacts include 304 stainless steel components resistant to corrosion, suitable for continuous operation in demanding commercial foodservice settings. The switch operates without requiring external power, simplifying integration into existing control systems. Certified for safety, this device supports HACCP compliance and features a 4.15" height, 6.1" width, and 7.95" depth for versatile placement in machinery lines. Its design promotes quick maintenance and inspection, reducing downtime in moderate-volume processing facilities.

Ideal for installing in automated conveyor systems or machine boundary detection in commercial kitchens.

A commercial limit switch is an industrial component used to detect the position of moving parts within machinery, providing control and safety functions. The York S1-02537344000 Limit Switch 215/185(o/c) Aut is configured with a contact mechanism capable of manual testing and automatic switching, positioned for use in moderate-usage foodservice environments such as processing lines or conveyor systems. It features a compact form factor with dimensions of approximately 6.1 inches wide, 7.95 inches deep, and 4.15 inches high, made with durable materials to withstand washdown and frequent operation. Typically installed in equipment requiring boundary detection or position monitoring, it supports regulatory compliance including HACCP standards and NSF-rated components for sanitation compliance.

Designed for steady operational workflows in small prep kitchens or processing stations, these limit switches support reliable position detection and safety monitoring with a compact footprint and robust construction. They handle recurring demands in institutional kitchens, providing durability and precision for manual and automated equipment. Suitable for machinery requiring consistent boundary control, these switches enable efficient daily food prep activities and machinery safety compliance.

The York S1-02537344000 limit switch features a stainless-steel contact arm designed for corrosion resistance, supporting operational temperatures up to standard ranges for industrial control components. It operates without external power, relying on mechanical contact activation, and measures 6.1 inches in width, 7.95 inches in depth, and 4.15 inches in height, with a weight of only 0.04 lbs. Certified through industry standards such as NSF and potentially UL, it ensures compliance for sanitation and safety regulations. The device's sealed contacts facilitate washdown cleaning, vital for maintaining hygiene in commercial food environments. Its design supports easy disassembly for maintenance and inspection.

This limit switch distinguishes itself through its robust stainless steel construction, sealed design supporting washdown cleaning, and precise boundary detection capabilities. Its compact, OEM format offers seamless integration into various machinery, supporting HACCP compliance and safety standards. Compared to similar components, it provides a reliable, corrosion-resistant solution with easy maintenance, reducing downtime and supporting continuous operation within commercial food processing environments.