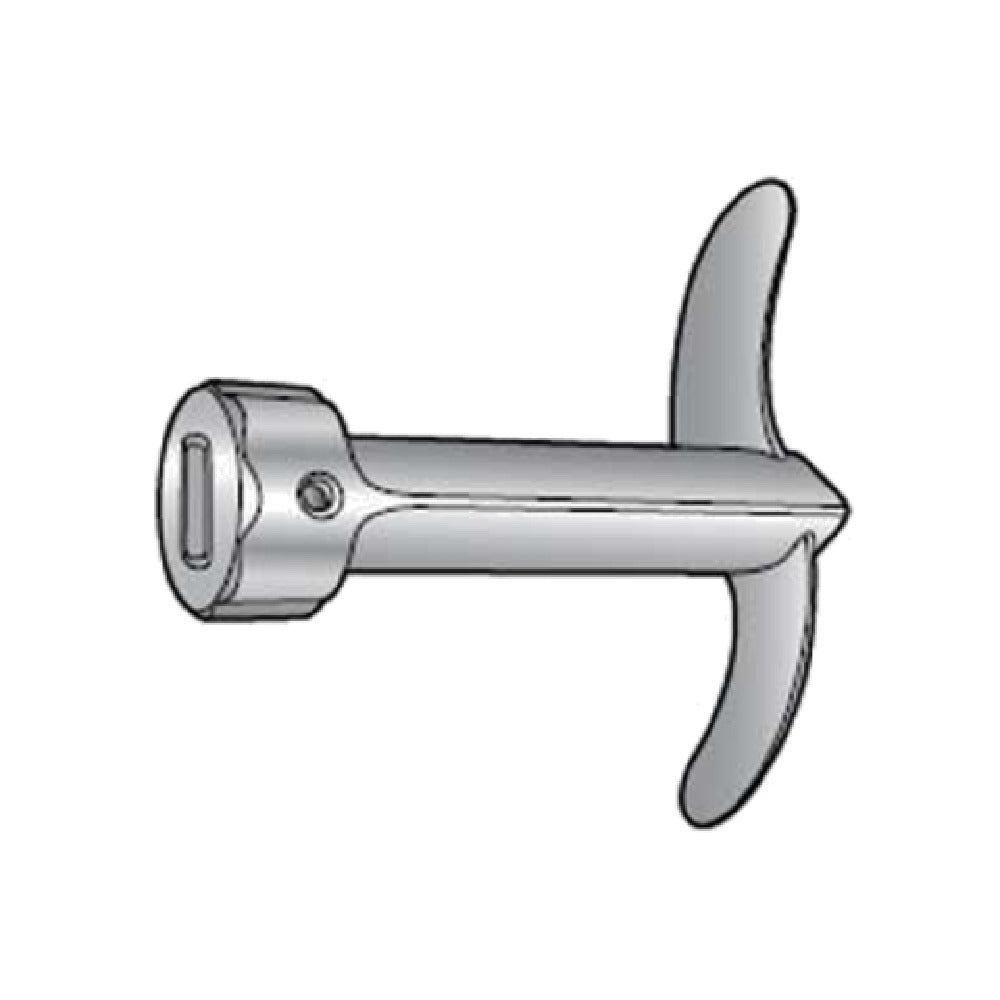

Alfa VCM-377 Aluminum Knead Shaft Fits Model 40 Replaces OEM 0377

Delivery to:

- Designed for Model 40 for optimal fit

- Corrosion-resistant aluminum ensures longevity

- Supports medium-throughput food processing

- View More Details

Best Price Guarantee

Best Price Guarantee

Secure Shopping

Secure Shopping

The Alfa VCM-377 Knead Shaft Aluminum VCM 40 is a precision-engineered replacement component designed specifically for commercial food processing environments. As part of Alfa International’s acclaimed line of food cutter parts and accessories, this shaft assembly is built from durable aluminum to ensure longevity and reliable performance. It fits model 40 units, replacing OEM part number 0377, as well as compatible with Stephan 0377, Hobart M-88258-2, and Berkel 88999-4. This component enhances operational efficiency by maintaining optimal kneading function, reducing downtime and the need for frequent maintenance, and ensuring consistent output in high-use applications. Its precise design and material integrity make it ideal for commercial kitchens and food manufacturing facilities requiring robust, quality parts for continuous operation.

The Alfa VCM-377 Knead Shaft aluminum construction offers high durability and corrosion resistance, supporting long-term use in demanding foodservice settings. Its standardized fit and precise dimensions facilitate easy replacement and integration within model 40 food cutters, streamlining maintenance workflows. Designed for medium-volume processing, this shaft ensures consistent kneading performance, reducing wear on other components, and providing reliable operation during extended shifts. Its compatibility with multiple OEM parts simplifies inventory management for commercial kitchen technicians, ensuring seamless service continuity.

Suitable for commercial food processing facilities seeking reliable spare parts for moderate throughput operations.

The Alfa VCM-377 Knead Shaft features a robust aluminum construction with precise dimensions tailored to fit model 40 food cutters, replacing OEM part 0377. It operates within standard technical parameters, supporting consistent kneading without requiring specialized electrical or cooling systems. Weighing approximately [insert weight], this shaft offers durability and ease of handling, with a design focused on seamless compatibility and longevity. Its corrosion-resistant aluminum finish ensures optimal performance in high-moisture environments, facilitating straightforward cleaning routines. The shaft’s dimensions, including length and diameter, are engineered to meet the strict tolerances necessary for precise kneading operations in commercial kitchens, food manufacturing, and industrial applications.

A commercial knead shaft is a critical component within industrial-grade food cutters and mixers, designed to facilitate consistent dough or mixture kneading. Typically constructed from durable materials such as aluminum or stainless steel, it integrates seamlessly into models like the Alfa VCM-377, working to ensure uniform processing in food production lines. Installed in food processing facilities, bakery operations, and industrial kitchens, it supports high-volume throughput environments by maintaining mechanical integrity and ease of maintenance. The Alfa VCM-377 Knead Shaft aluminum VCM 40 exemplifies this by replacing OEM parts with precision engineering suited for ongoing commercial use, particularly in medium-volume production scenarios.

Built for medium-volume production, the Alfa VCM-377 seamlessly integrates into commercial food cutters, supporting consistent kneading and processing efficiency. Alfa International’s durable aluminum design ensures long-term reliability and compatibility with proven OEM parts. The part’s rugged construction and precise fit make it suitable for industrial kitchens, food manufacturing, and large-scale catering operations, optimizing workflow and minimizing maintenance disruptions.

Alfa VCM-377 distinguishes itself through its high-quality aluminum construction, precise OEM fit, and corrosion resistance, providing superior durability compared to standard replacement parts. Its design supports quick installation and low-maintenance operation, improving efficiency in medium-volume food processing environments. With compatibility across multiple OEM models, it offers a reliable, restaurant-ready solution that enhances operational uptime and product consistency.

Product Description

From the manufacturer