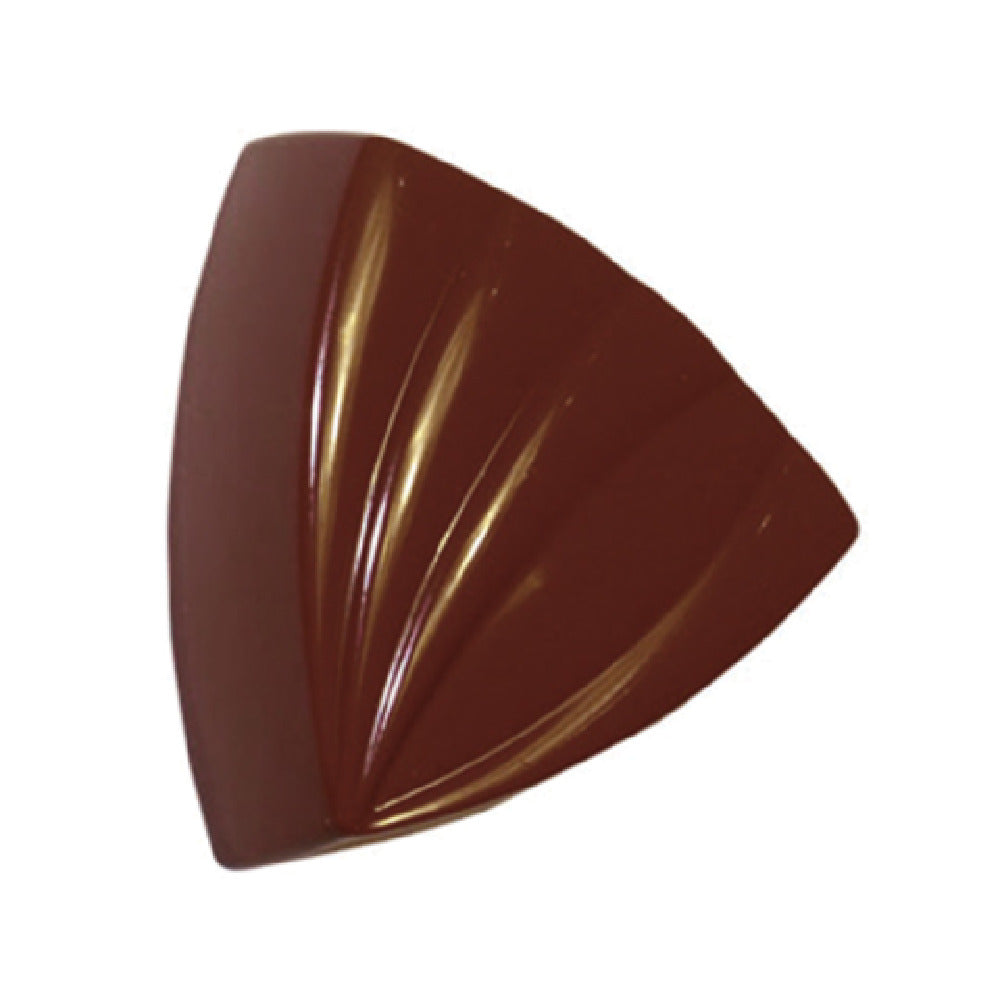

Matfer 380165 1-1/3 Inch Chocolate Mold Striped Triangles 28 Cavities Polycarbonate

Delivery to:

- Impact-resistant polycarbonate construction ensures durability

- 28 cavities enable high-volume batch processing

- Precise cavity dimensions support uniform shaping

- View More Details

Best Price Guarantee

Best Price Guarantee

Secure Shopping

Secure Shopping

The Matfer 380165 Chocolate Mold Striped Triangles 28 Per Sheet is a professional-grade confectionery tool designed specifically for high-volume commercial chocolate and candy production. Crafted from transparent polycarbonate, this durable mold features 28 precisely aligned striped triangular cavities measuring 1-1/3 inches in length and width, with a height of 1/2 inch. Its smooth surface facilitates easy release and cleaning, making it ideal for continuous industrial use in professional kitchens, including bakery and candy manufacturing facilities. The product’s technical specifications emphasize its robustness and suitability for precise, uniform casting operations, supporting high-efficiency fabrication of decorative chocolate triangles and related confections.

The Matfer 380165 Chocolate Mold offers a non-flexible, high-impact polycarbonate construction optimized for commercial confectionery workflows. Its 28-cavity design ensures consistent portioning and uniform appearance for large batch production. The smooth interior surface enhances product release while simplifying cleaning routines. Designed for professional use, this mold supports high-volume candy and chocolate shaping, integrating seamlessly into automated or manual production lines. Its durability under frequent use reduces replacement costs for busy kitchen operations, enabling efficient workflow management.

Designed for professional candy and chocolate manufacturing, this mold suits medium-volume facilities aiming for consistent results and efficiency.

The Matfer 380165 Chocolate Mold features robust, non-flexible polycarbonate construction with a capacity designed for 28 individual cavities. Each cavity measures 1-1/3 inches in length and width, with a height of 1/2 inch, enabling precise shaping of striped triangular chocolates. The mold operates within a typical temperature range suitable for confectionery processes and withstands frequent cleaning in commercial dishwashers. Its transparency allows visual inspection during production, supporting quality assurance. The overall dimensions support easy integration into standard production stations, with a shipping weight optimized for handling. The product is compatible with professional kitchen cleaning routines, and its impact-resistant design reduces downtime. Power and electrical specifications are not applicable; the focus remains on static durability and thermal stability.

A commercial candy mold is a manufacturing tool used for shaping confectionery products during high-volume production. Specifically, the Matfer 380165 is a professional-grade, impact-resistant polycarbonate mold with 28 cavities designed for creating striped triangular chocolates. Installed in confectionery and bakery facilities, it supports consistent product sizing and rapid batch processing, ideal for medium-volume foodservice operations such as candy manufacturing, bakery production, or specialty chocolate shops. Its construction ensures durability and ease of cleaning, making it suitable for continuous industrial use and high-quality confections.

High-quality confectionery molds like the Matfer 380165 serve medium-volume production needs with durable construction, precise cavity formation, and efficient batch output. Designed for confectionery and bakery applications, these molds enable consistent, professional results during automation or manual workflows, supporting reliable and repeatable candy shaping in commercial kitchens and food manufacturing facilities.

Choosing the Matfer 380165 offers a combination of impact-resistant polycarbonate construction and precise cavity design, setting it apart from standard molds. Its robustness under high-frequency use reduces replacement cost, while the smooth surface ensures quick release and sanitation. With a compact footprint tailored for professional confectionery environments, it enhances workflow efficiency and product presentation in busy commercial kitchens.