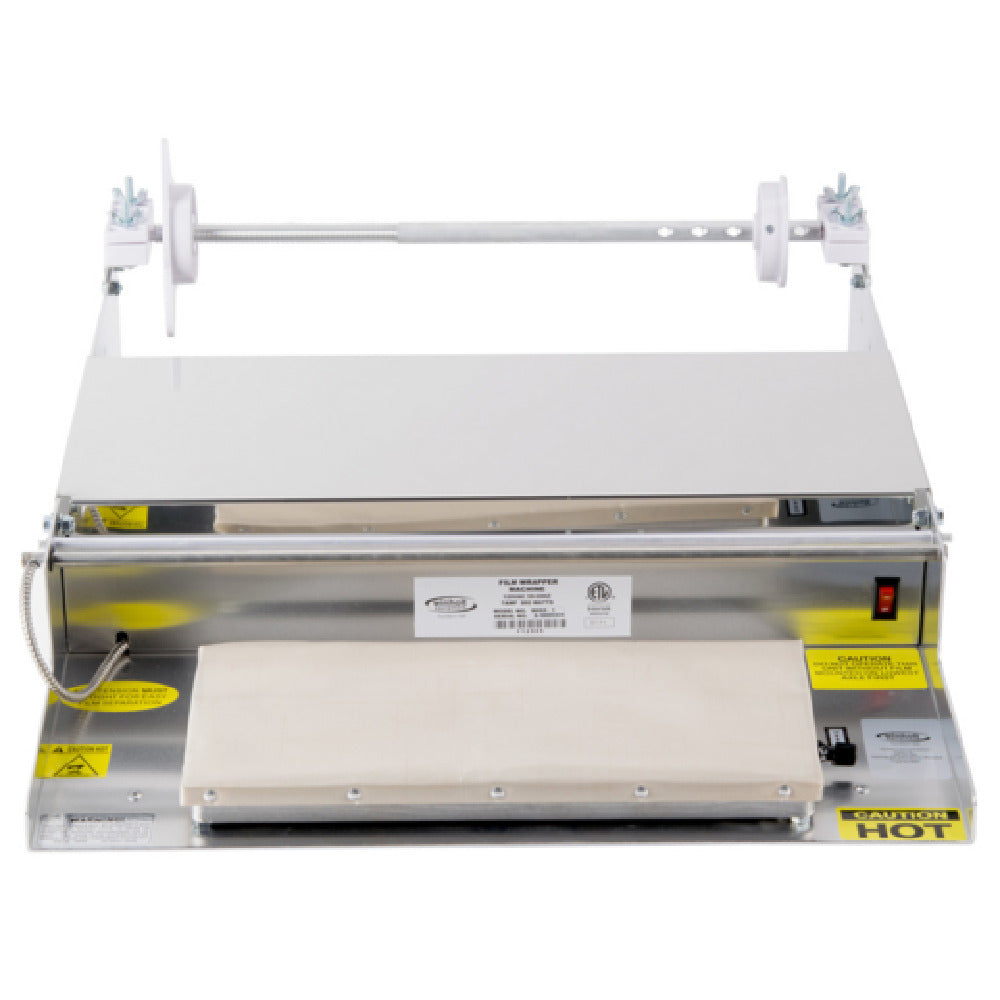

Winholt WHSS-1 24 Inch Film Wrapping Dispenser Electric Aluminum and Stainless Steel with Hot Plate

Delivery to:

- Constructed from durable aluminum and stainless steel

- Supports up to 200 wraps daily for moderate throughput

- 6" x 15" Teflon-covered hot plate for uniform heat

- View More Details

Best Price Guarantee

Best Price Guarantee

Secure Shopping

Secure Shopping

The Winholt WHSS-1 Film Wrapping Dispenser is a commercial-grade heat seal machine designed for precise and efficient film applications in foodservice environments. Constructed from durable aluminum and stainless steel, this counter-type wrapping solution features a 6" x 15" Teflon-covered hot plate and mounting axles, capable of holding a single film roll with a 3" diameter core. Engineered for steady daily workflows, the dispenser enhances packaging consistency in small to medium-volume kitchens, catering stations, and institutional settings. Its robust build and reliable thermal performance support HACCP protocols and facilitate streamlined food wrapping operations within professional foodservice facilities.

The Winholt WHSS-1 film wrapping dispenser optimizes manual film sealing tasks in foodservice settings by offering a 6" x 15" Teflon-coated hot plate for uniform heat application. Its aluminum and stainless steel construction ensures durability, while the simple plug-in operation provides easy setup and maintenance. Designed to accommodate one film roll with a 3" core diameter, it supports consistent packaging workflows for up to 200 wraps daily, making it suitable for moderate production needs in commercial kitchens. Certified by ETL, this dispenser meets industry sanitation standards and supports HACCP compliance, ideal for back-of-house operations requiring reliable equipment for manual film sealing.

Suitable for stabilizing film wrapping procedures in commercial kitchens or catering stations requiring dependable manual sealing.

A commercial heat seal machine is a device used to precisely apply heat to seal films or plastic wraps for packaging applications within foodservice operations. The Winholt WHSS-1 is classified as a heat seal machine, with features including a 6" x 15" Teflon-covered hot plate and aluminum and stainless steel construction. It is typically installed in back-of-house food prep areas, ensuring secure wrapping of products while maintaining hygienic standards and supporting HACCP compliance. Used primarily in institutions, catering, and small restaurant kitchens, it provides consistent, manual film sealing for medium-volume packaging tasks, with a typical shipping time of 1 to 2 days and CE and ETL certifications.

Designed for small commercial spaces requiring reliable manual film sealing, the Winholt WHSS-1 offers a durable construction and consistent performance. Its moderate throughput supports daily food packaging tasks, making it suitable for small prep kitchens, caterers, and institutional kitchens handling steady workflows.

The Winholt WHSS-1 features a self-contained design with a 6" x 15" Teflon-coated hot plate powered by a 115V, 60Hz, single-phase connection, drawing up to 8 amps. Its aluminum and stainless steel construction ensures longevity and sanitation compliance, with a shipping weight of 29 lbs. The unit includes mounting axles to hold a single film roll with a 3" core, and it offers ETL certification for safety and performance. Its dimensions measure 24" W x 22.25" D x 5" H, making it suitable for installation in back-of-house food prep areas, service counters, or packaging stations. Designed for routine maintenance, the dispenser allows quick cleaning and hassle-free operation, supporting HACCP protocols.

The Winholt WHSS-1 distinguishes itself through a heavy-duty aluminum and stainless steel build that ensures durability and sanitation. Its compact profile suits small foodservice spaces and supports manual film sealing with a 6" x 15" hot plate, enabling reliable performance during daily packaging. Compared to similar models, it offers ETL certification, a roll capacity of 3" core, and straightforward operation, increasing efficiency and reducing downtime in institutional and catering environments.

Product Description

Certifications

ETL

This item has been evaluated by Edison Testing Laboratories (ETL) and has been found to meet or exceed electrical and gas safety standards.