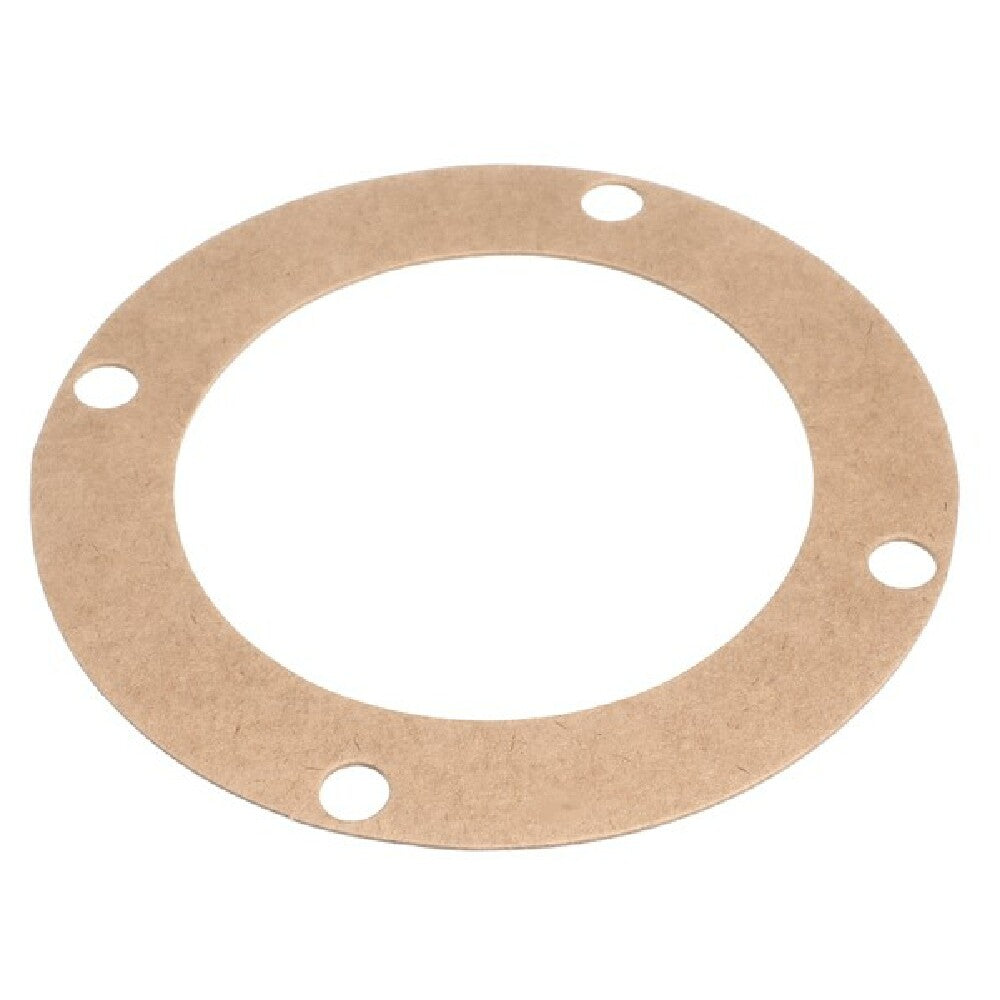

AllPoints 00-975811 Gasket Motor/base veg.fiber for OEM Food Equipment

Delivery to:

- Precisely fits motor/base sealing applications

- Vegetative fiber offers chemical resistance

- Easy installation reduces maintenance time

- View More Details

Best Price Guarantee

Best Price Guarantee

Secure Shopping

Secure Shopping

The Somat Company 00-975811 Gasket Motor/base (veg.fiber) is a specialized sealing component designed for OEM applications within the food processing industry. Constructed from vegetative fiber, this gasket ensures precise sealing between motor bases and seating surfaces, contributing to optimal equipment performance. Its durability addresses vibration, heat, and chemical exposure commonly encountered in industrial food manufacturing, making it suitable for machinery requiring reliable sealing solutions. This gasket’s technical design provides a robust, resistant interface, preventing leaks and contamination. It is engineered to meet the demands of high-precision assembly and maintenance, with exact dimensions for seamless integration into commercial-grade motor assemblies, ensuring extended operational lifespan and consistent performance in food processing environments.

This gasket features an exact fit for motor/base sealing, with high resistance to chemical and temperature exposure typical in industrial kitchens. Its vegetative fiber composition offers ease of installation and maintenance, ensuring sustained performance during routine servicing. Designed for OEM use, it provides a reliable seal to minimize downtime and equipment failure. Compatible with various motor configurations, it supports hygienic operation in high-volume food production settings, promoting workflow efficiency and sanitation compliance.

Ideal for OEM motor assemblies requiring reliable, durable gaskets in commercial food manufacturing installations.

The Somat Company 00-975811 gasket is designed with dimensions that accommodate a height of 0.7 inches, a width of 10.8 inches, and a depth of 12.65 inches, facilitating precise installation in OEM motor chambers. Made from vegetative fiber material, it offers excellent chemical and heat resistance, with a typical weight of only 0.22 lbs, simplifying handling and replacement. It is non-hazardous and fabricated to endure operating conditions in food processing equipment. The gasket is made from food-safe fiber, compatible with cleaning protocols, and tailored for long-lasting sealing in industrial environments. Its design supports maintenance and assembly in factory settings, optimizing workflow for commercial food production lines without requiring disassembly of entire units.

A commercial gasket is a sealing component engineered for industrial and high-volume food processing machinery, designed to prevent leaks between mechanical parts such as motor bases and housings. The Somat Company 00-975811 Gasket Motor/base (veg.fiber) is a precisely crafted OEM part made from vegetative fiber, ensuring chemical resistance and long-term durability under demanding operating conditions. Typically installed in motor assemblies in food manufacturing environments, it provides essential sealing to uphold sanitation standards and equipment reliability, making it suitable for applications requiring tight, maintenance-friendly seals in commercial food processing lines and equipment maintenance routines.

Designed for OEM sealing in food machinery, this gasket from AllPoints 00-975811 offers high durability and precise fit for industrial motor bases, ideal for maintenance in commercial kitchens and large-scale production facilities. It supports steady operation with minimal downtime, suited for moderate to high-volume workflows, and ensures optimal machine sealing for consistent operation in demanding foodservice environments.

Compared to standard gaskets, the AllPoints 00-975811 utilizes vegetative fiber for enhanced chemical and heat resistance, ensuring long-lasting sealing performance. Its precise dimensions fit motor bases accurately, reducing installation time and maintenance complexity. Designed for OEM applications, it improves operational efficiency and maintains hygiene standards in commercial food processing facilities. Its lightweight, durable build minimizes equipment downtime and promotes consistent sealing performance across demanding workflows.