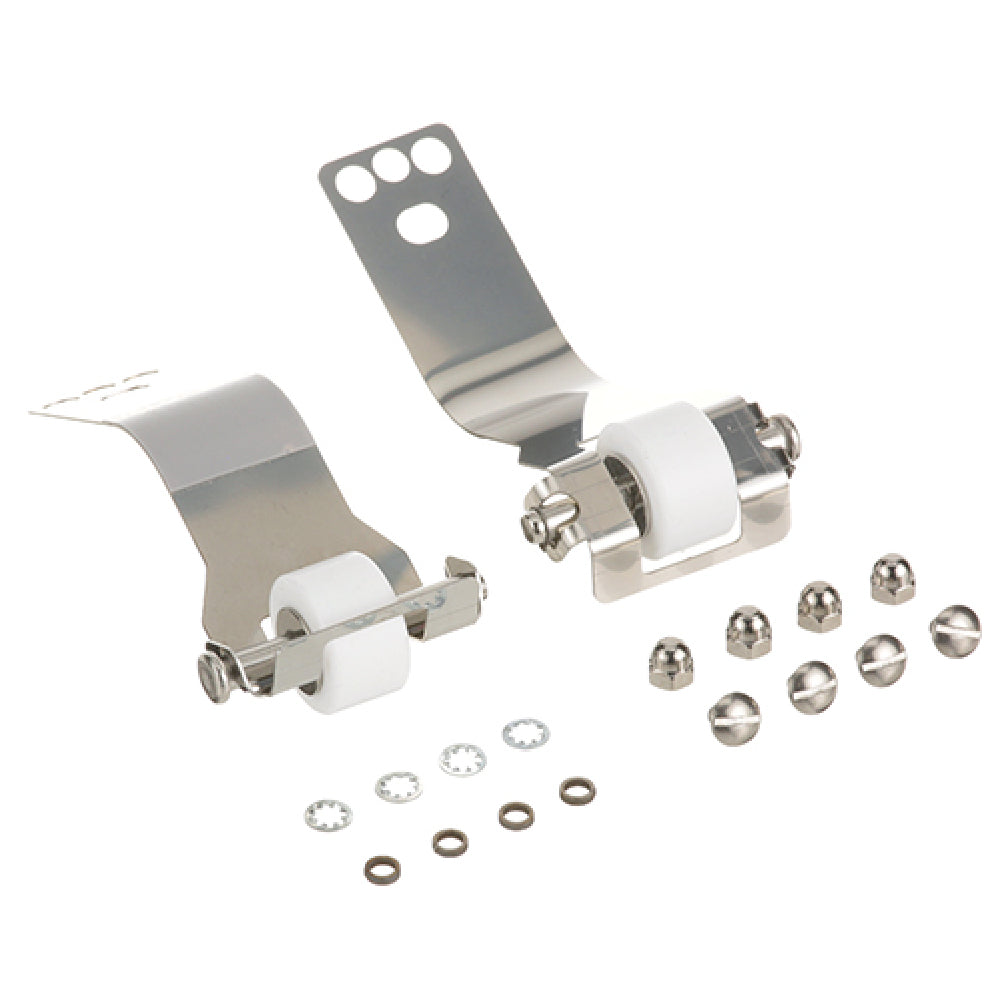

AllPoints 7000186 4-3/4 Inch Roller Tensioner Kit With Teflon Roller and Hardware

Delivery to:

- Maintains optimal tension in high-volume systems

- Corrosion-resistant hardware ensures long-term durability

- Designed for seamless integration into OEM conveyors

- View More Details

Best Price Guarantee

Best Price Guarantee

Secure Shopping

Secure Shopping

The Roundup - AJ Antunes 7000186 Roller Tensioner Kit (pk2) is a precision-made OEM component designed for commercial food processing equipment. Crafted in the United States, this tensioner assembly includes two 4-3/4" x 2" rollers with high-performance Teflon rollers and durable hardware. Suitable for enhancing conveyor and packaging systems, this kit ensures optimal belt tension and smooth operation in demanding foodservice environments. Its precise dimensions and robust construction make it ideal for installation in industrial-grade equipment used in high-volume food production lines and bakery applications, providing reliable tensioning to prevent slippage and maintain workflow efficiency.

The 7000186 roller tensioner assembly offers a critical solution for maintaining belt integrity in commercial foodservice and processing equipment. Its dual-roller design improves tension consistency, reducing downtime caused by belt misalignment. Manufactured with high-quality materials tailored for long-term performance, the kit allows straightforward installation and maintenance, ideal for conveyor systems in high-output kitchens and production facilities. Designed for easy integration into existing machinery, it supports continuous workflow and minimizes operational disruptions.

Ideal for replacing worn tensioners in commercial bakery, packaging, or processing conveyor systems requiring reliable operation.

The 7000186 roller tensioner kit is engineered for high-performance industrial use, featuring two 4-3/4" x 2" rollers with Teflon-coated surfaces, designed to withstand continuous operation in food processing environments. The assembly is constructed from corrosion-resistant hardware with a total weight of only 0.3 lbs, making it easy to handle during installation. Its dimensions of 3" width, 4" depth, and 1" height suit a wide range of conveyor systems. The kit requires no electrical connections and is suitable for use in setups with standard industrial supply voltages. It supports high-stress applications with its durable build, providing long-lasting tensioning support under demanding workload conditions. Its corrosion-resistant hardware and Teflon rollers facilitate cleaning and maintenance, ensuring compliance with industry hygiene standards. The assembly is designed for straightforward disassembly and replacement in routine maintenance procedures, featuring included hardware for secure mounting and reliable operation.

A commercial roller tensioner kit is a mechanically operated assembly used to maintain precise belt tension in conveyor systems within food processing and packaging facilities. The Roundup - AJ Antunes 7000186 model includes dual rollers engineered for durability and ease of adjustment, supporting continuous operation in moderate workloads typical of high-volume foodservice production. Installed in processing equipment such as bakery conveyors or packaging lines, it ensures smooth belt movement and reduces maintenance frequency, making it suitable for mid-volume industrial environments requiring reliable tension support.

These durable, factory-built tensioners are constructed for reliable operation in moderate workload food processing environments. Roundup 7000186 is optimized for conveyor applications, supporting workflow efficiency and long-term performance in high-output kitchens and manufacturing lines.

The AllPoints 7000186 roller tensioner kit offers a robust, OEM-grade solution for conveyor belt maintenance that surpasses similar aftermarket components. Its corrosion-resistant hardware and Teflon rollers enhance longevity, supporting demanding food production workflows. The kit's straightforward installation process reduces downtime, while its compact design allows seamless integration into existing equipment, elevating operational efficiency and sanitation standards in commercial kitchens and processing plants.