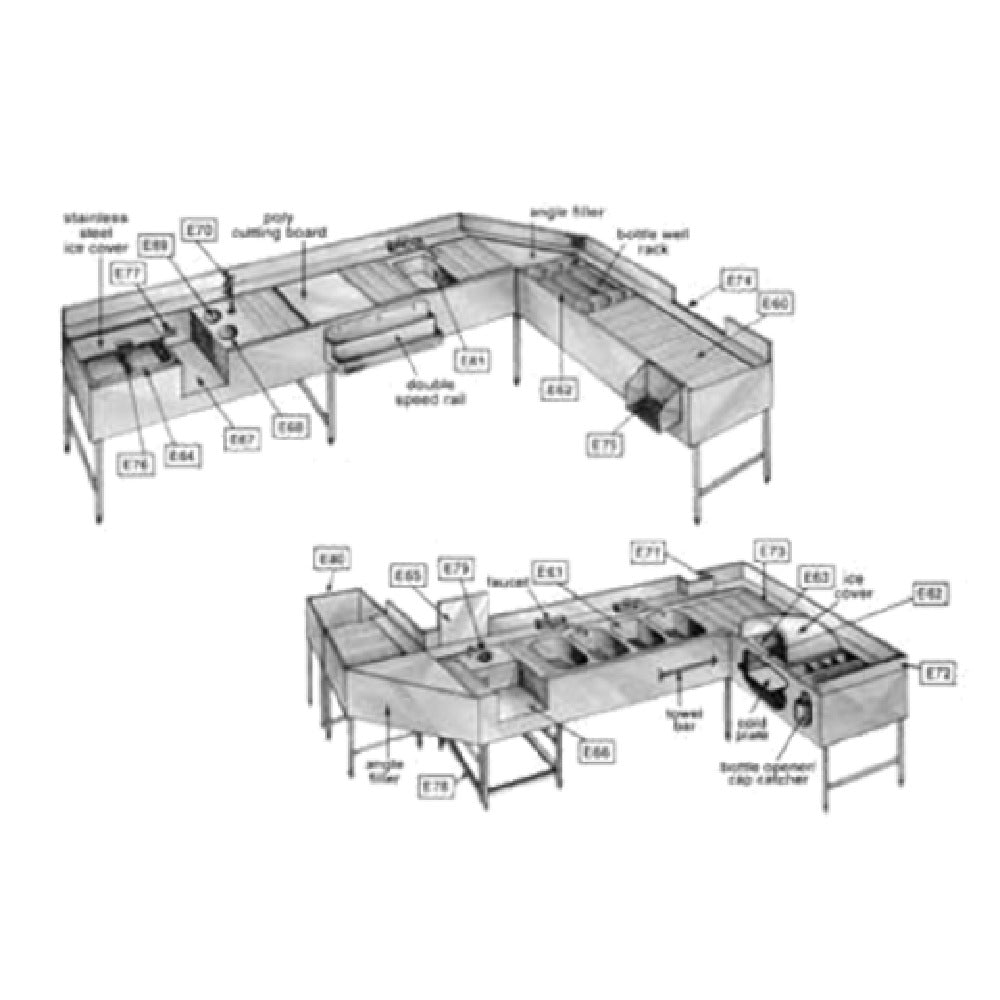

Eagle E70-1800 8 Inch Stainless Steel Glass Filler with Precise Water Flow

Delivery to:

- Optimized for high-volume beverage dispensing

- Constructed from durable, corrosion-resistant stainless steel

- Provides precise water flow control for accuracy

- View More Details

Best Price Guarantee

Best Price Guarantee

Secure Shopping

Secure Shopping

The Eagle E70-1800 Glass Filler 1800 Series is a commercial-grade, stainless steel beverage equipment component designed for high-demand foodservice environments. Engineered by Eagle Group, this glass filler provides a durable, corrosion-resistant solution for efficient beverage service lines. Its precise fabrication ensures consistent water flow, minimal splash, and ease of cleaning, making it suitable for busy restaurants, cafes, and hospitality establishments. The model E70-1800 features a robust construction engineered to withstand frequent use, with a focus on seamless integration into various beverage dispensing stations. Its technical specifications include a stainless steel finish and a compact footprint tailored for undercounter or countertop installations, ensuring reliable performance in commercial kitchens.

Designed for commercial beverage stations, the Eagle E70-1800 delivers precise water flow with a durable stainless steel construction for long-term use. It features seamless mounting for quick installation, low-maintenance operation, and resistance to corrosion. Suitable for high-volume settings, its ergonomic design minimizes splash and simplifies cleaning. The unit's streamlined profile supports workflow efficiency in busy foodservice environments.

Ideal for commercial establishments requiring reliable glass filling in high-throughput environments.

The Eagle E70-1800 Glass Filler is built with a stainless steel body, featuring dimensions suitable for compact installation, measuring approximately 8 inches wide, 4 inches deep, and 6 inches high, with a weight of around 2.5 lbs for ease of handling. This model operates with standard typical water pressure and does not require electrical connection. It offers a flow capacity calibrated to deliver consistent filling speeds, supporting high-volume beverage dispensing. Its construction emphasizes food safety, with corrosion-resistant materials compatible with frequent cleaning routines. Designed for durability, the E70-1800 withstands daily use in busy kitchens, with a corrosion-resistant finish and a simplified assembly process. The unit is compatible with standard plumbing and installation techniques, supporting workflow efficiency and sanitation protocols.

A commercial glass filler is a specialized beverage equipment component used in high-volume foodservice settings to dispense water into glassware efficiently. Typically installed as part of a bar or drink station, the Eagle E70-1800 Glass Filler ensures precise water flow, minimizes splash, and facilitates quick filling processes. These units are constructed from durable, corrosion-resistant materials and are designed for seamless integration with existing plumbing systems. They are suitable for restaurant bars, hospitality venues, and cafes, where reliable and hygienic beverage dispensing is critical for operational flow. The Eagle E70-1800 is engineered to handle frequent use, providing consistent performance in busy environments.

The Eagle E70-1800 is a top-rated commercial glass filler built for consistent flow and durability, suitable for high-volume beverage stations in busy hospitality environments. Its robust design ensures long-term performance during continuous operation in restaurant and bar applications.

Choosing the Eagle E70-1800 ensures a resilient, high-performance glass filler tailored for demanding foodservice operations. Its stainless steel construction offers corrosion resistance, while its simple design supports quick installation and maintenance. Compared to similar units, it provides superior durability, precise water flow control, and seamless integration into existing setups, enhancing efficiency and sanitation in busy commercial kitchens.

Product Description

From the manufacturer