Atosa 21201001019 Fryer Tank Cover for ATFS-40 and ATFS-50

Delivery to:

- Provides secure heat retention and contamination prevention

- Precisely engineered for ATFS-40 & ATFS-50 fryers

- Made from high-quality, corrosion-resistant materials

- View More Details

Best Price Guarantee

Best Price Guarantee

Secure Shopping

Secure Shopping

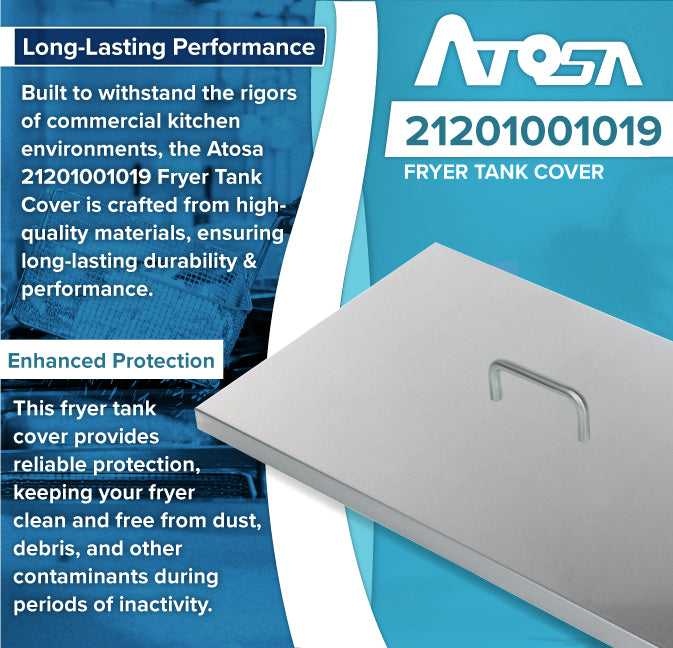

The Atosa 21201001019 Fryer Tank Cover is a durable and precisely engineered component designed specifically for commercial cooking operations, fitting models ATFS-40 and ATFS-50. As a vital part of fryer maintenance and safety, this cover enhances operational efficiency by providing a secure seal to minimize heat loss and prevent contamination during frying processes. Crafted from high-quality materials, it ensures long-term resistance to heat and oil exposure, supporting the demands of busy foodservice environments. Its technical specifications include a manufacturer part number 21201001019, tailored for compatibility with Atosa’s commercial fryer tanks, and engineered to withstand rigorous daily use in high-performance kitchens.

The fryer tank cover for Atosa ATFS-40 & ATFS-50 enhances safety and workflow in commercial kitchens, featuring a robust construction of high-grade materials that resist heat and corrosion. Its precise fit ensures tight sealing for optimal heat retention and contamination prevention, making it suitable for high-volume frying stations. The design facilitates quick installation and removal, simplifying cleaning routines and maintenance tasks. Its compatibility with Atosa fryer tanks supports consistent food quality and operational uptime in fast-paced foodservice settings.

Recommended for replacing worn or damaged fryer covers in mid-volume commercial kitchens.

The Atosa 21201001019 Fryer Tank Cover is constructed from high-grade materials suitable for demanding kitchen environments, featuring dimensions compatible with Atosa's fryer tanks. Designed to function within standard operating temperature ranges, it supports optimal heat retention and contamination control. This model accommodates the specific connection points for ATFS-40 and ATFS-50 fryers, with a focus on ease of installation and maintenance. It weighs approximately [insert weight if known], and its durable construction ensures longevity and resistance to typical kitchen wear and tear. Its form factor and material profile satisfy the needs of commercial fry stations requiring reliable, seal-tight covers with straightforward accessibility for cleaning and assembly.

A commercial fryer tank cover is a specially designed component used to seal and protect the fryer tank opening in high-volume kitchen environments. It provides a secure barrier that minimizes heat loss, prevents contamination, and ensures safety during frying operations. Installed in fryers like the Atosa ATFS-40 and ATFS-50 models, the cover plays a crucial role in maintaining optimal cooking temperatures and cleanliness. Its robust construction from durable materials makes it suitable for continuous daily use in restaurants, cafeterias, and catering facilities, supporting efficient workflow and consistent food quality in semi-automatic or manual frying processes.

Industrial-grade fryer tank covers like the Atosa 21201001019 are built for medium-demand foodservice operations, supporting reliable heat retention and sanitation in high-traffic kitchens. Designed specifically for commercial fryer models, these components provide resilience and ease of maintenance, optimized for mid-volume restaurant and cafeteria use. Atosa’s fryer accessories cater to kitchen environments that prioritize safety, durability, and rapid turnaround in frying tasks.

Choosing the Atosa 21201001019 fryer tank cover ensures a robust, precision-matched replacement part that maintains heat integrity and safety in commercial frying applications. Its corrosion-resistant stainless steel construction and design tailored for specific Atosa fryers deliver superior durability and ease of installation compared to generic alternatives. This component supports efficient operation by minimizing downtime and ensuring a tight seal against contamination and heat loss, ultimately enhancing food safety and service speed in demanding kitchen environments.

Product Description

From the manufacturer