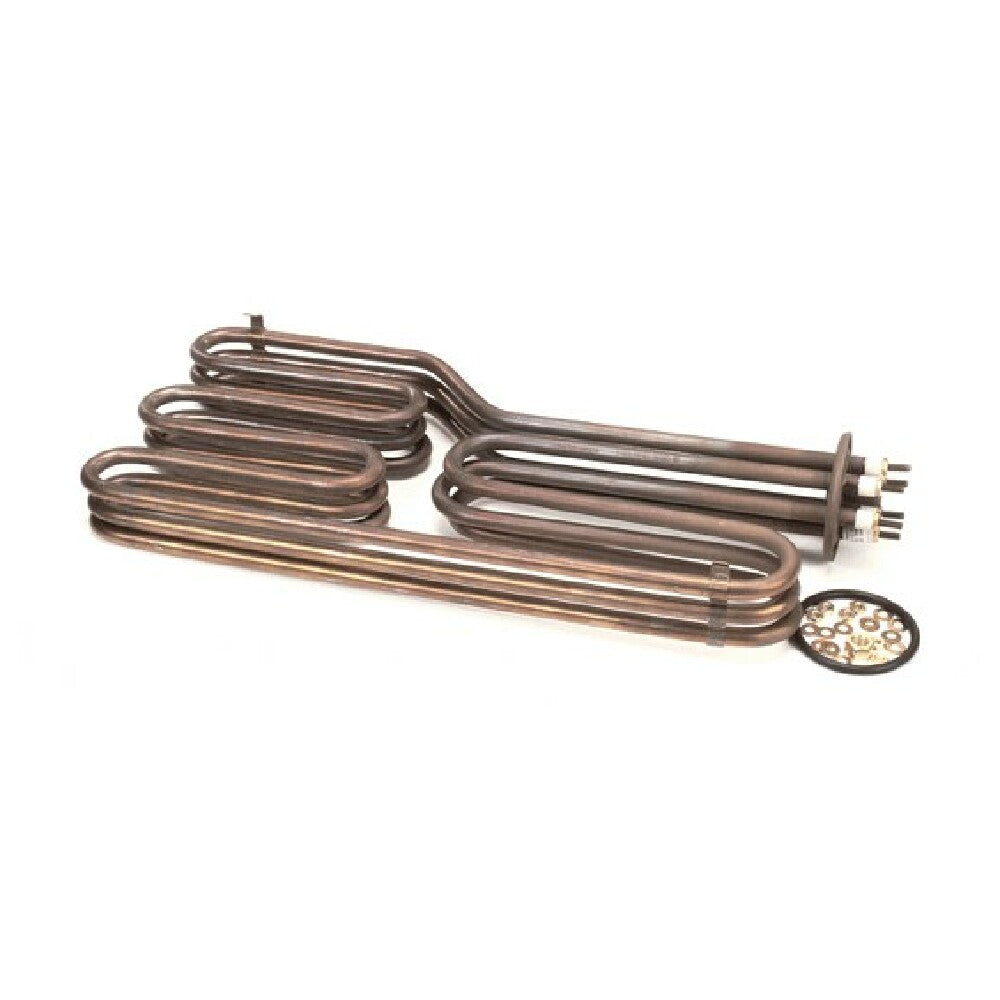

AllPoints 00-974568-00004 8 Inch Electric Heater Element 15 Kw Stainless Steel

Delivery to:

- High wattage output for rapid heating

- Robust stainless steel construction durability

- Easy installation with OEM compatibility

- View More Details

Best Price Guarantee

Best Price Guarantee

Secure Shopping

Secure Shopping

The GE/Hobart 00-974568-00004 Heater Element 15 Kw 440v is a high-performance electric heating component designed for commercial foodservice applications requiring reliable and efficient thermal output. Engineered by GE/Hobart, this 15-kilowatt heater element operates at 440 volts, providing consistent heat transfer for industrial ovens, dishwashers, and other large-scale thermal equipment. Its robust construction ensures durability in demanding environments, making it suitable for high-traffic commercial kitchens and food processing facilities. With precise specifications, it supports seamless integration into existing electrical systems, ensuring optimal operation of power-intensive appliances without compromising safety or efficiency.

This heater element delivers high wattage output with a durable steel element resistive component designed for continuous operation in busy commercial kitchens. Its design accommodates straightforward installation and maintenance, with corrosion-resistant materials suitable for food-safe environments. Ideal for replacement in high-capacity industrial heating units, it supports consistent workflow and energy efficiency across a wide range of commercial cooking and cleaning equipment.

Ideal for replacing worn-out heating elements in industrial food processing or commercial dishwashing equipment

The GE/Hobart 00-974568-00004 heater element is engineered for 440V electrical systems operating at 15 kW, suitable for three-phase applications with a typical current draw fitting standard industrial specifications. Its construction features a resilient steel resistive element housed in a stainless steel shell, ensuring longevity in demanding settings. The physical dimensions include a height of 3.25 inches, width of 8.05 inches, and depth of 19.55 inches, with a product weight of approximately 6.44 lbs. Designed for straightforward installation, it offers compatibility with GE/Hobart equipment, supporting high-temperature operation within safe limits and complying with material safety standards for food industry surfaces. This OEM part combines durability with precise electrical performance, making it a reliable choice for maintaining the operational efficiency of commercial heating systems.

A commercial heater element is a high-capacity electrical component designed to generate heat in industrial and foodservice equipment. Specifically, the GE/Hobart 00-974568-00004 model serves as a replacement part for high-wattage processes such as industrial food prep, dishwashing solutions, or large-scale heating applications. It features a resilient steel resistive core housed in stainless steel to withstand demanding usage, supporting continuous operation in busy foodservice environments. This OEM heater element is installed within equipment like industrial ovens and dishwashers, ensuring consistent thermal performance for mid-volume operations or heavy-duty workflow scenarios.

Designed for medium workload industrial kitchens, the GE/Hobart 00-974568-00004 offers unmatched build quality, facilitating reliable heating in commercial food processing. It supports continuous operation, making it suitable for mid-volume restaurant or hospital hydration stations. GE/Hobart OEM heater elements ensure precise thermal control and durability for high-demand foodservice activities.

Compared to other OEM heating elements, the AllPoints 00-974568-00004 distinguishes itself through high-grade stainless steel construction, ensuring long-term durability even in corrosive environments. Its precise specifications and compatibility support seamless integration within existing GE/Hobart systems, reducing downtime and maintenance costs. The robust design enhances operational efficiency by providing consistent heat output, improving equipment reliability, and maintaining food safety standards.