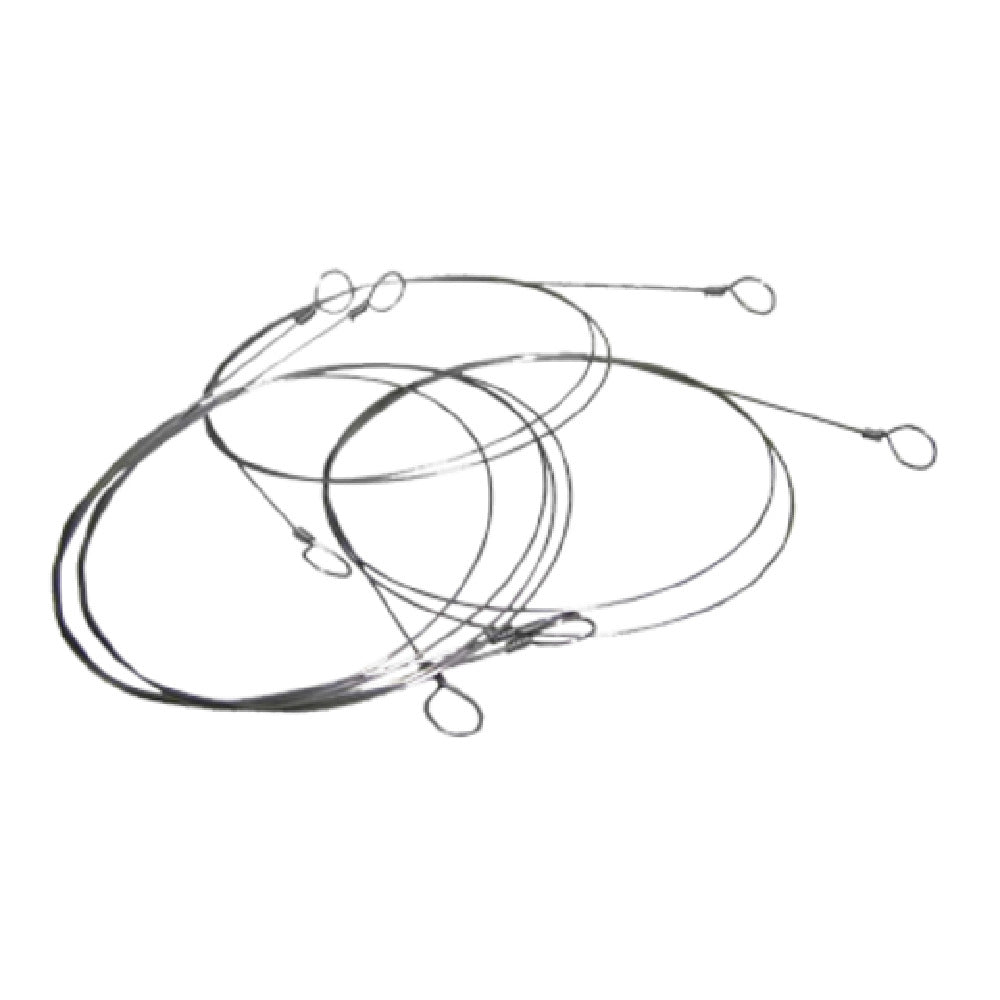

The Omcan 10061 (10061) Cheese Cutter Wire 36" is a durable, high-performance component designed for commercial cheese slicing applications. Manufactured by Omcan USA, this replacement wire measures 36 inches in length and is optimized for use in professional foodservice environments, including deli counters and cheese prep stations. Constructed from corrosion-resistant materials, it ensures precise cuts and long-term reliability. This cheese cutter wire is a critical tool for establishing clean, consistent slices in high-volume operations, reducing waste and improving workflow efficiency. The technical specification includes a 36-inch length suitable for standard commercial cheese cutter frames, making it a versatile part for various slicer models, with an emphasis on durability and ease of maintenance.

Top Omcan 10061 Features

This cheese cutter wire offers precise, consistent slicing for commercial cheese preparation, featuring robust construction from high-grade materials for durability. Its 36-inch length is designed for easy installation and long-lasting performance in busy foodservice environments. Specifically engineered for efficient workflow, it minimizes downtime and ensures clean cuts with minimal effort. Compatibility with standard cheese cutter frames makes it ideal for deli counters, cheese processing lines, and catering setups. The wire's design simplifies replacement, promoting quick maintenance and operational uptime.

- Functionality: Ensures precise, uniform cheese slices in high-volume settings

- Durability: Made from corrosion-resistant, high-tensile materials for long-term use

- Ease of Maintenance: Simple to replace with common cheese cutter frames

- Application Fit: Compatible with standard commercial cheese slicers and deli equipment

- Workflow Benefit: Enhances slicing efficiency, reducing downtime in busy kitchens

Ideal for commercial cheese slicing needs requiring reliable wire replacements.

Omcan 10061 Technical Specs

The Omcan 10061 cheese cutter wire is manufactured by Omcan USA, with a length of 36 inches and weighing only 1 pound, making it lightweight yet durable. It is crafted from corrosion-resistant high-tensile materials suitable for food processing environments. The wire is designed to fit standard cheese cutter frames, facilitating quick installation and replacement, which minimizes operational downtime. It is compatible with various cheese slicer models used in deli counters, catering, and cheese processing stations. The product's construction supports easy cleaning and maintains performance over prolonged use, making it a reliable component for medium-volume cheese slicing workflows.

- Length: 36 inches for standard commercial cheese slicers

- Material: High-grade corrosion-resistant steel

- Weight: 1 lb for easy handling and installation

- Compatibility: Fits most standard cheese cutter frames

- Operation Environment: Suitable for high-use deli and cheese prep stations

- Maintenance: Simple replacement, minimal downtime, easy cleaning

What is a commercial cheese cutter wire

A commercial cheese cutter wire is a essential component used in professional cheese slicing equipment, designed to produce uniform, clean slices for high-volume foodservice operations. Typically made from stainless steel or high-tensile alloys, these wires are manufactured to withstand heavy usage in deli counters, catering kitchens, and cheese processing lines. The (10061) cheese cutter wire from Omcan USA, in particular, is a 36-inch replacement part suited for standard commercial slicers, enabling precise and efficient slicing of cheese blocks. Its durability and ease of installation make it ideal for medium-volume foodservice settings where consistency and reliability are critical for product presentation and workflow productivity.

Top commercial cheese cutter wires for deli and cheese prep settings

Designed for high-quality cheese slicing, Omcan 10061 cheese cutter wires are built for durability and precise performance in foodservice kitchens. Omcan 10061 cheese cutter wires are ideal for medium-volume cheese processing environments, supporting efficient workflow and clean operation. Suitable for delis, catering, and cheese production stations, this product ensures consistency and longevity in professional applications, making it ideal for various commercial cheese slicing needs.

- Operation Type — suitable for deli counters and cheese prep stations

- Kitchen Setting — designed for compact commercial kitchens and foodservice outlets

- Foodservice Category — optimal for cheese slicing and deli operations

- Workload Qualifier — supports moderate throughput in busy environments

- Use Case — best for manual cheese slicing and replacement parts logistics

Why Choose Omcan 10061 (10061) Cheese Cutter Wire 36"

Why Choose Omcan 10061 cheese cutter wire over other replacement options? Its high-grade corrosion-resistant construction ensures long-lasting, reliable performance, and compatibility with a wide range of commercial slicers enhances operational flexibility. Engineered for ease of maintenance and quick replacements, it minimizes downtime, optimizing workflow in busy delis and cheese production lines. Its precise design supports consistent, clean slices, improving product presentation and operator efficiency in high-volume foodservice environments.

- Compact, corrosion-resistant design for longevity in heavy use

- Universal fit for most commercial cheese slicer models

- High tensile strength reduces wire breakage during slicing

- Easy to replace and maintain, reducing operational delays

- Ideal for restaurant-ready cheese processing equipment