Matfer 186700MC Mandoline Slicer 12-1/2 Inch Width with 3 Blades and Safety Pusher -

Delivery to:

- High-volume precision with stainless steel blades

- Supports rapid, consistent cuts with three blades

- Engineered for durability and safety standards

- View More Details

Best Price Guarantee

Best Price Guarantee

Secure Shopping

Secure Shopping

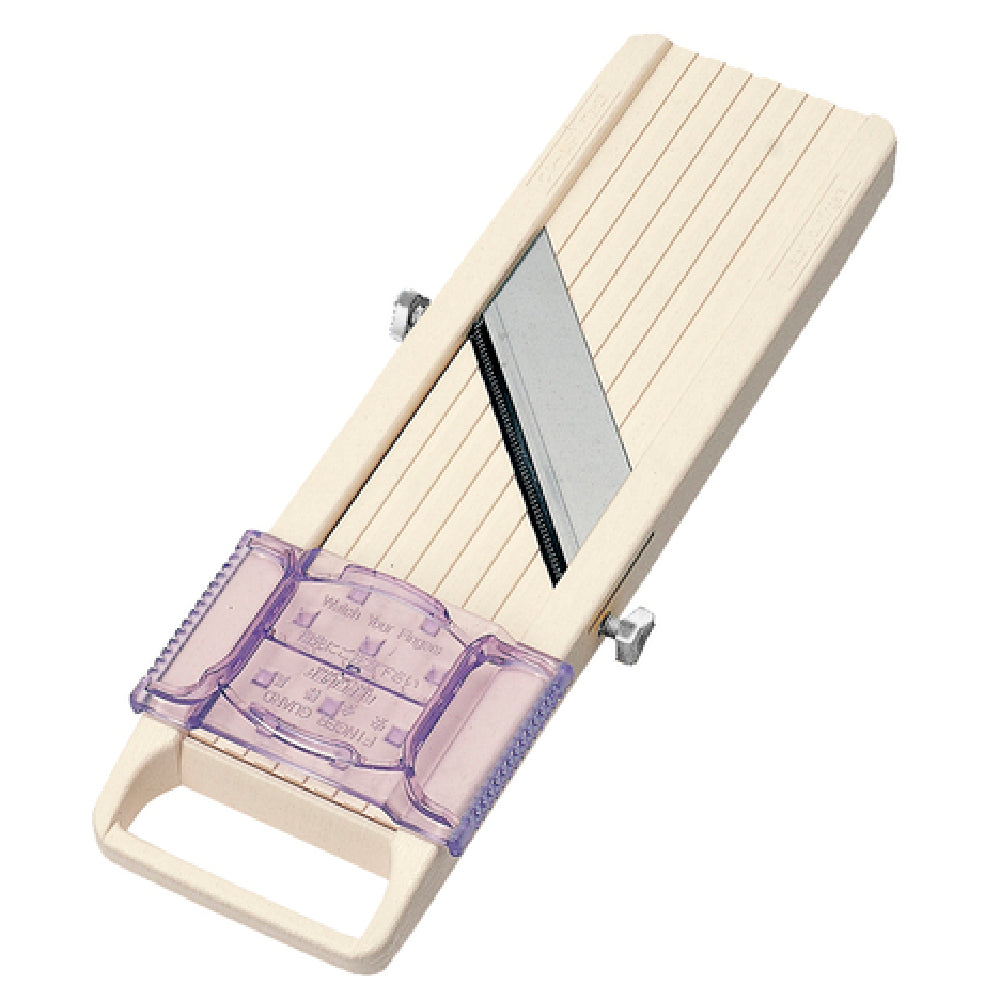

The Matfer 186700MC Benriner "Little Beni" Mandoline Slicer is a precision-made, chef-level slicing tool designed for professional food processing environments. Measuring 12-1/2 inches long by 3-1/2 inches wide, this mandoline features stainless steel blades mounted on a durable polypropylene frame, making it suitable for high-volume vegetable and fruit preparation in commercial kitchens. The model includes three interchangeable blades, allowing for varied slicing textures, and a safety pusher to ensure operator safety during continuous operation. Constructed in Japan, it is engineered for precise, consistent cuts with a focus on durability and efficiency in fast-paced culinary settings.

The Benriner "Little Beni" Mandoline Slicer offers professional-grade slicing with stainless steel blades for sharpness and longevity, and a polypropylene frame for durability. Its compact size facilitates easy handling and cleaning, ideal for high-turnover kitchens. Designed for quick blade exchanges, it supports versatile slicing tasks from julienne to thick-cut slices, fitting seamlessly into workflow automation for continuous prep cycles. The safety pusher enhances operational safety, making it suitable for medium-volume foodservice production.

Designed for medium-volume vegetable prep in commercial kitchens, the Benriner Mandoline is ideal for consistent, efficient slicing tasks.

The Matfer 186700MC Mandoline Slicer features a stainless steel blade construction to ensure cutting precision and longevity, supported by a plastic frame for lightweight durability. It measures 12.5 inches in length and 3.5 inches in width, fitting comfortably into standard workstations. Powered solely by manual operation, it requires no electrical connection, making it versatile and easy to clean with disassembly for maintenance. The unit has a max operating temperature suitable for cold and room-temperature foods, maintaining food safety standards through food-grade materials. Its ergonomic design includes a safety pusher to prevent hand injuries during slicing operations. The product is shipped in a case, with each unit weighing approximately [insert weight as applicable], making it suitable for high-turnover kitchens requiring quick setup and cleaning.

Electrical Requirements: None, manual operation only

Cooling Method: Not applicable

Production Capacity: Variable based on user operation, suitable for medium-volume prep

Construction & Finish: Stainless steel blades, polypropylene frame

Color: Standard polypropylene color

A commercial mandoline slicer is a precision manual food preparation tool designed for uniform vegetable and fruit slicing in professional kitchens. The Matfer 186700MC Benriner "Little Beni" models are built with stainless steel blades and a sturdy polypropylene frame, suitable for high-volume slicing tasks. They are typically installed on prep stations or held in hand for versatile use, ideal for applications such as salad bars, prep lines, and catering services. These slicers support consistent cut quality, enhancing efficiency and presentation in restaurant and institutional settings.

Built for precise manual operation, the Matfer 186700MC Benriner Mandoline Slicer ensures consistent slicing performance in medium-volume kitchen workflows, ideal for vegetable and fruit preparation in professional foodservice. Matfer's model offers durable stainless steel blades and a compact design for optimal integration into busy culinary environments.

Matfer’s 186700MC mandoline offers a professional-grade design fitted for consistent, safe slicing in commercial kitchens. Its stainless steel blades and durable polypropylene frame deliver longevity and precise cuts, outperforming many competitor models in durability and safety features. The ergonomic design minimizes operator fatigue and maximizes workflow efficiency, making it suitable for high-turnover food prep environments.