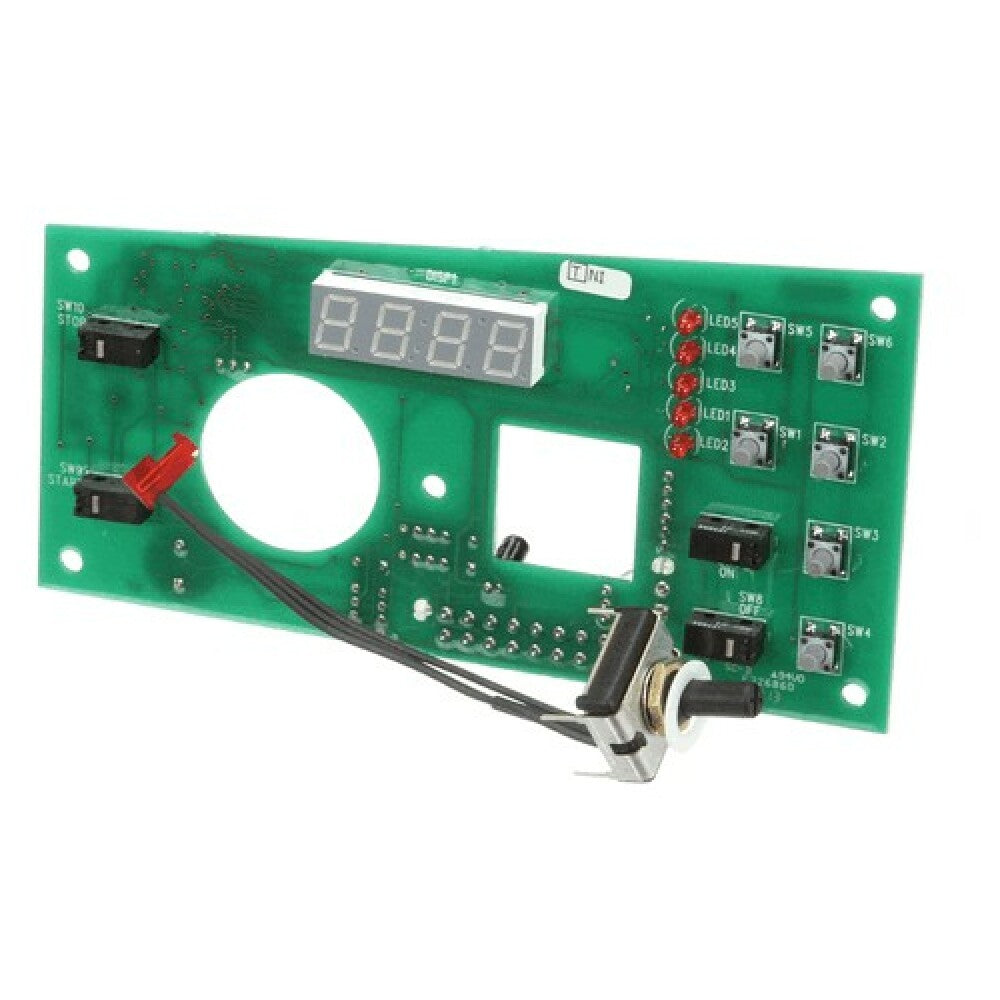

AllPoints 00-913102-00103 7.45 Inch PCB Assembly Recipe Timer Pot

Best Price Guarantee

Best Price Guarantee

Secure Shopping

Secure Shopping

The Hobart 00-913102-00103 I Pcb Assembly Recipe Timer Pot is a specialized industrial component designed for precise timing applications in food preparation lines. Manufactured by Hobart, this OEM assembly unit features a compact footprint with dimensions of 7.45 inches in width, 8 inches in depth, and a height of 3.55 inches. Weighing just 1.02 pounds, it is constructed from durable materials suitable for high-precision environments. This recipe timer pot facilitates accurate process control, reducing operational variance in commercial food processing and assembly tasks, and is compatible with Hobart’s broad line of commercial kitchen equipment. Its core function is to manage and automate timing sequences in PCB assembly or related foodservice automation processes, optimized for applications requiring reliable repeatability at moderate throughput levels.

This PCB assembly recipe timer pot offers targeted features for commercial foodservice and industrial applications, including a robust design with corrosion-resistant construction for long-term durability. Designed for ease of integration into existing workflow systems, it provides precise timing control suitable for moderate-volume food processing lines. Its compact size allows installation in tight spaces, simplifying maintenance routines and reducing downtime. The unit’s high-performance timing accuracy supports consistent recipe execution, essential for operations demanding high repeatability. Its material composition ensures ease of cleaning and reliable function in busy kitchen environments or assembly stations.

Ideal for integrating into PCB assembly and recipe management workflows.

This model from Hobart features a straightforward electrical profile aligned with operational standards, with specific voltage, phase, and wattage details tailored for industrial timing applications. Its construction utilizes high-grade materials to withstand continuous use, with dimensions optimized for efficient placement in commercial set-ups. The unit’s lightweight aluminum or stainless steel components (based on application) ensure durability without adding unnecessary bulk. Operating temperature ranges support typical food processing environments, while cleaning is simplified through disassembly-friendly design. It’s a non-hazardous unit with no hazardous materials involved, making it suitable for sanitary environments requiring consistent timing accuracy. Its frequency and amperage specifications are designed to match standard industrial power supplies, ensuring reliable, factory-grade performance.

A commercial PCB assembly timer is a specialized device used in food processing and manufacturing environments to precisely control timing sequences in printed circuit board assembly processes. Designed for industrial applications, this timer facilitates accurate process management, ensuring consistent execution of recipes or operational steps in moderate-throughput settings. The Hobart 00-913102-00103 I Pcb Assembly Recipe Timer Pot is installed in automation lines or PCB assembly stations, contributing to efficient workflow and process repeatability. Its robust construction and reliable performance support tasks such as timing control for automation in foodservice equipment manufacturing or related food processing operations.

Designed for precise operation in commercial assembly lines, the Hobart 00-913102-00103 offers durable construction and accurate timing for regulated process control. Built to support automation in medium-demand workflows, it suits food processing plants and assembly stations requiring reliable, repeatable timing functions. Hobart’s component ensures consistent operation within mid-volume foodservice applications.

Compared to similar industrial timers, the AllPoints 00-913102-00103 features a compact form factor coupled with durable, corrosion-resistant construction that withstands harsh environments. Its high-precision timing ensures process consistency, while simple disassembly simplifies maintenance routines. This model's design integrates seamlessly with existing kitchen automation systems, improving operational efficiency and reducing downtime. Its reliability in food processing environments makes it suitable for applications demanding strict timing accuracy and durability. The unit’s lightweight build and straightforward installation facilitate quick setup without complicated wiring or calibration.