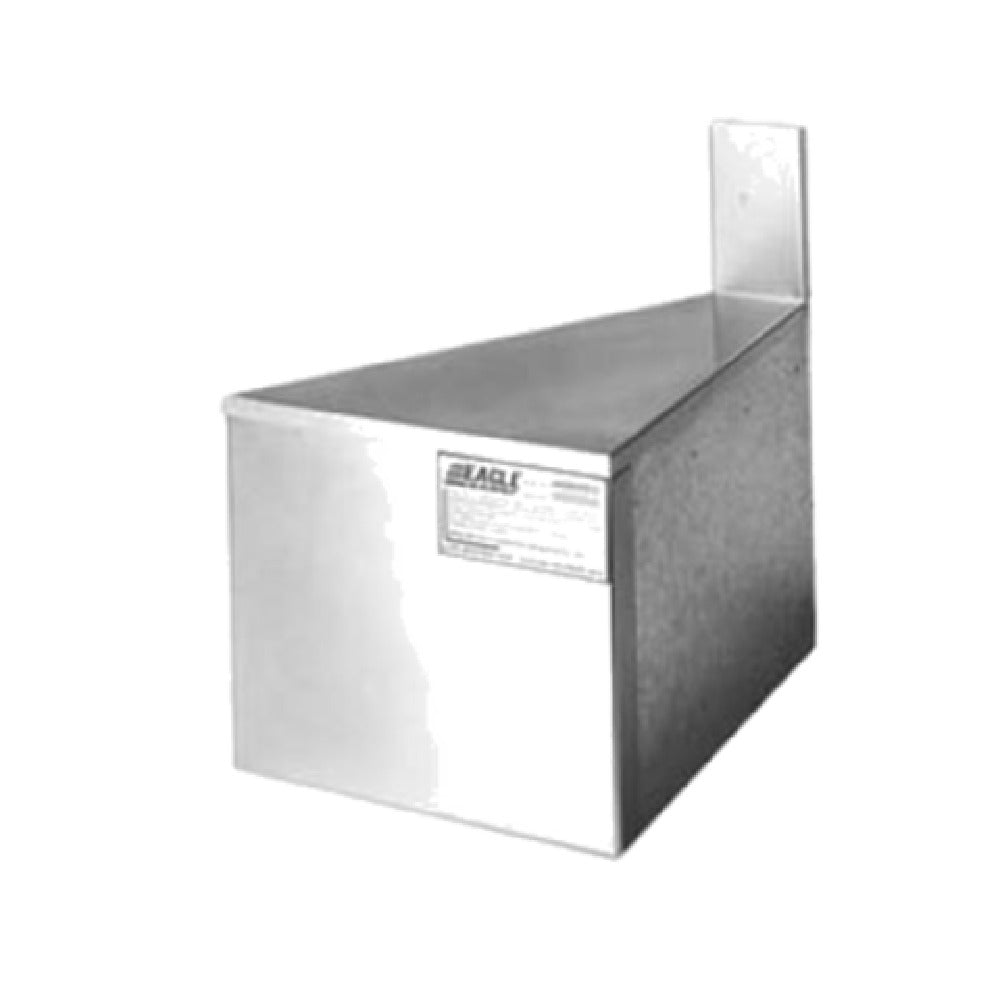

Eagle MF60-22 22 Inch 60 Degree Angle Underbar Angle Filler Stainless Steel with Flat Top

Delivery to:

- Optimized for precise coverage with 60° angle

- Constructed from corrosion-resistant 20/304 stainless steel

- Flat top design supports efficient prep areas

- View More Details

Best Price Guarantee

Best Price Guarantee

Secure Shopping

Secure Shopping

The Eagle MF60-22 2200 Series Front Angle Filler is a high-performance underbar equipment component designed for commercial kitchens and beverage stations. Crafted from 20/304 stainless steel, it features a flat top surface with a 60° corner fill angle, measuring 22 inches front to back for optimal coverage. Its robust construction and precise design enable seamless integration into restaurant prep areas, bar setups, or catering environments, offering durability and efficient workflow support for moderate-volume foodservice operations. The model emphasizes ease of maintenance and durability, providing a reliable solution for high-traffic settings requiring consistent sanitation and performance.

The Eagle MF60-22 provides a precisely angled 60° corner fill with a robust stainless steel finish, designed for quick cleaning and long-term durability. Its flat top surface allows for smooth preparation or placement of bar tools, while its stainless steel construction ensures resistance to corrosion and daily wear. Engineered for medium workload environments, it fits seamlessly into countertop setups, offering ergonomic access and consistent performance. The unit’s design facilitates streamlined workflow in hospitality kitchens and bar areas, simplifying installation and daily maintenance for commercial foodservice operators.

Ideal for installation in wine bars, beverage stations, or underbar setups where precise coverage and durability are critical.

The Eagle MF60-22 model features a stainless steel construction optimized for commercial environments, with a 22-inch width and a 60° corner fill angle. It operates as a no-legs unit with a flat top surface, making it compatible with various countertop configurations. The unit weighs approximately 20 lbs, ensuring stability while maintaining ease of installation. It does not specify electrical requirements or refrigeration, as it functions solely as a stationary filler component. Its splash zone measures 4 inches, contributing to splash control in busy bar settings. The finish, in stainless steel, provides excellent resistance to corrosion and ease of cleaning, suitable for daily sanitation routines. Shipping typically occurs within 8-10 weeks, with a freight class of 100 for transportation planning.

A commercial underbar angle filler is a stainless steel fixture designed to precisely fill gaps between bar equipment or countertops, improving workflow and sanitation. The Eagle MF60-22 is engineered for moderate-volume beverage and prep stations, featuring a 60° angled corner fill with a flat top for added surface area. Typically installed in underbar or beverage preparation areas, it enhances coverage while maintaining ease of cleaning and durability, making it suitable for busy hospitality environments and restaurant service stations.

Built with high-quality stainless steel, these units support seamless installation and reliable performance in hospitality kitchens. Eagle MF60-22, crafted for mid-volume beverage and food prep workflows, offers durable performance, corrosion resistance, and ergonomic functionality in restaurant-ready settings.

The Eagle MF60-22 distinguishes itself through its durable stainless steel finish, precise 60° angle, and flat top surface designed for ease of cleaning and functional integration into underbar setups. Its robust construction ensures longevity in high-traffic environments, while the no-legs design simplifies installation and maintenance. Compared to similar models, the MF60-22 offers a superior combination of corrosion resistance, ergonomic design, and reliable performance tailored for hospitality operators seeking standard-setting equipment that promotes operational efficiency and sanitation.

Product Description

From the manufacturer