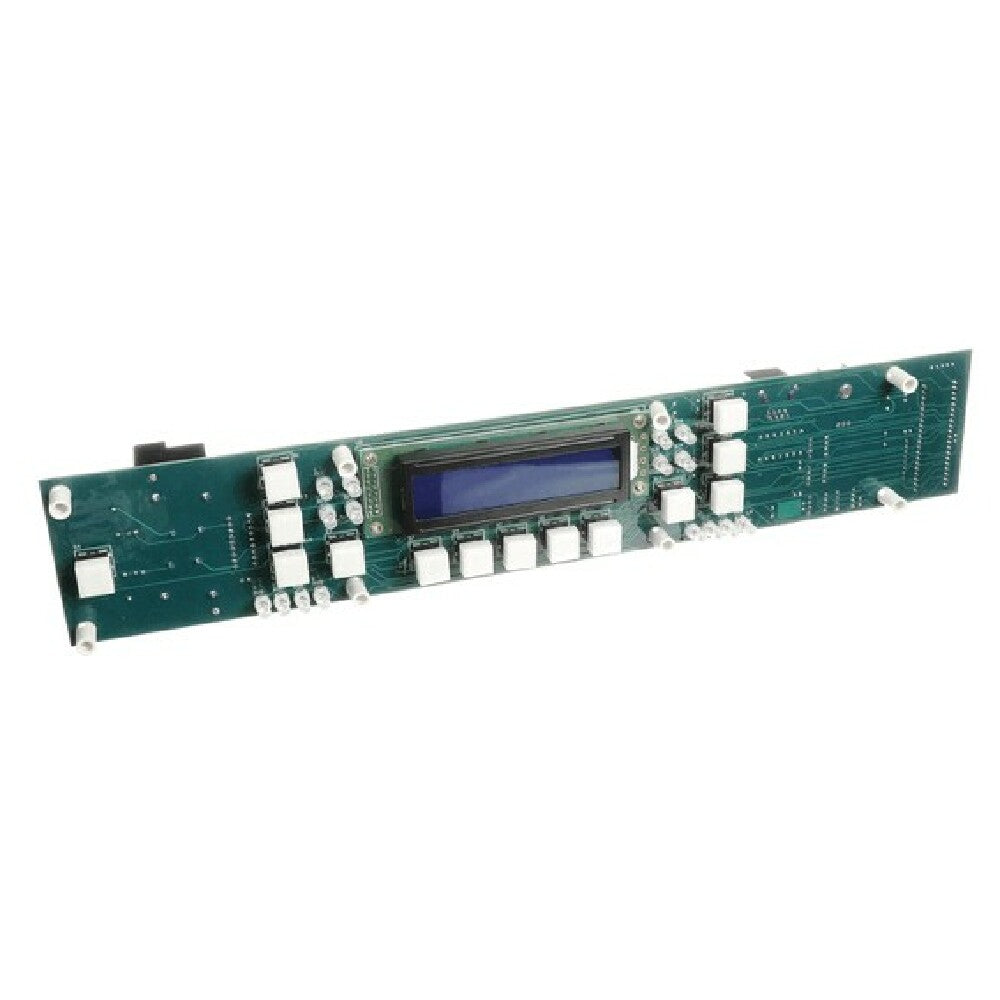

AllPoints DX186160028 3.55 Inch Control Board for Kitchen Equipment

Delivery to:

- Compact 3.55" width for seamless integration

- Operates with 16" depth supporting medium workloads

- Durable construction ensures long-term reliability

- View More Details

Best Price Guarantee

Best Price Guarantee

Secure Shopping

Secure Shopping

The Dinex DX186160028 Hmi Control Board is an OEM electronic component designed for precision control and integration within advanced kitchen automation systems. Manufactured by Dinex, this control board features a compact 3.55" width, 16" depth, and a height of 3.05", ideal for seamless installation in controlled environments. Its robust construction ensures durability in demanding commercial kitchen applications, providing reliable operation in foodservice equipment that requires electronic management and user interface control. This control board is engineered to enhance workflow efficiency through simplified integration with existing systems, making it suitable for medium-volume food production facilities and equipment requiring precise operational oversight.

The Dinex DX186160028 Hmi Control Board offers advanced electronic control for commercial kitchen equipment, with precise interface capabilities. Its durable construction ensures long-term performance in busy foodservice environments, while its compact size allows for easy replacement and maintenance. Designed for integration with various appliances, it provides reliable operation in medium-volume workflows, facilitating seamless automation and user management.

Optimal for replacing or upgrading control interfaces in commercial kitchen systems needing reliable electronic regulation

The Dinex DX186160028 Hmi Control Board operates on a standard electrical setup, typically requiring a low-voltage power source compatible with 3.55" width, 16" depth, and 3.05" height units. Its construction employs durable electronic-grade materials for consistent performance, suitable for installation within temperature ranges common to commercial kitchen environments. The board’s design ensures compatibility with multiple appliances, supporting medium workload scenarios such as automated food preparation or processing stations. With a weight of 0.68 lbs, it provides a lightweight but robust solution for OEM replacement needs. Maintenance involves straightforward disassembly for inspection or replacement, with no need for complex cooling systems. It’s engineered for longevity, resisting typical operational stresses in commercial foodservice settings.

A commercial control board is an electronic component that manages and regulates functions within foodservice equipment, such as ovens, dishwashers, or automated systems. It serves as the interface between user inputs and machine operations, providing reliable control over temperature, timing, and other critical parameters. The Dinex DX186160028 Hmi Control Board is designed for precise control, installation in professional kitchen appliances, and compatibility with OEM systems. It is used in medium-volume food production environments—installed in equipment like automated processing stations or control panels—making it essential for maintaining operational accuracy and efficiency in busy foodservice settings.

Designed for professional kitchens, OEM control boards like Dinex DX186160028 provide reliable electronic management and durability. They are suitable for installation in automated food processing and preparation equipment, supporting consistent operation in medium-volume workflows across commercial foodservice environments. These control boards facilitate seamless integration with existing systems, improving operational accuracy and reducing maintenance needs.

AllPoints DX186160028 control board offers a self-contained, reliable OEM solution with a robust design tailored for medium-volume commercial kitchens. Its high-grade electronic components ensure long-term performance and consistent control in various appliances, while its compact footprint simplifies installation and maintenance. The board’s integrated interface capabilities improve workflow automation and operational precision, setting it apart from more generic alternatives.