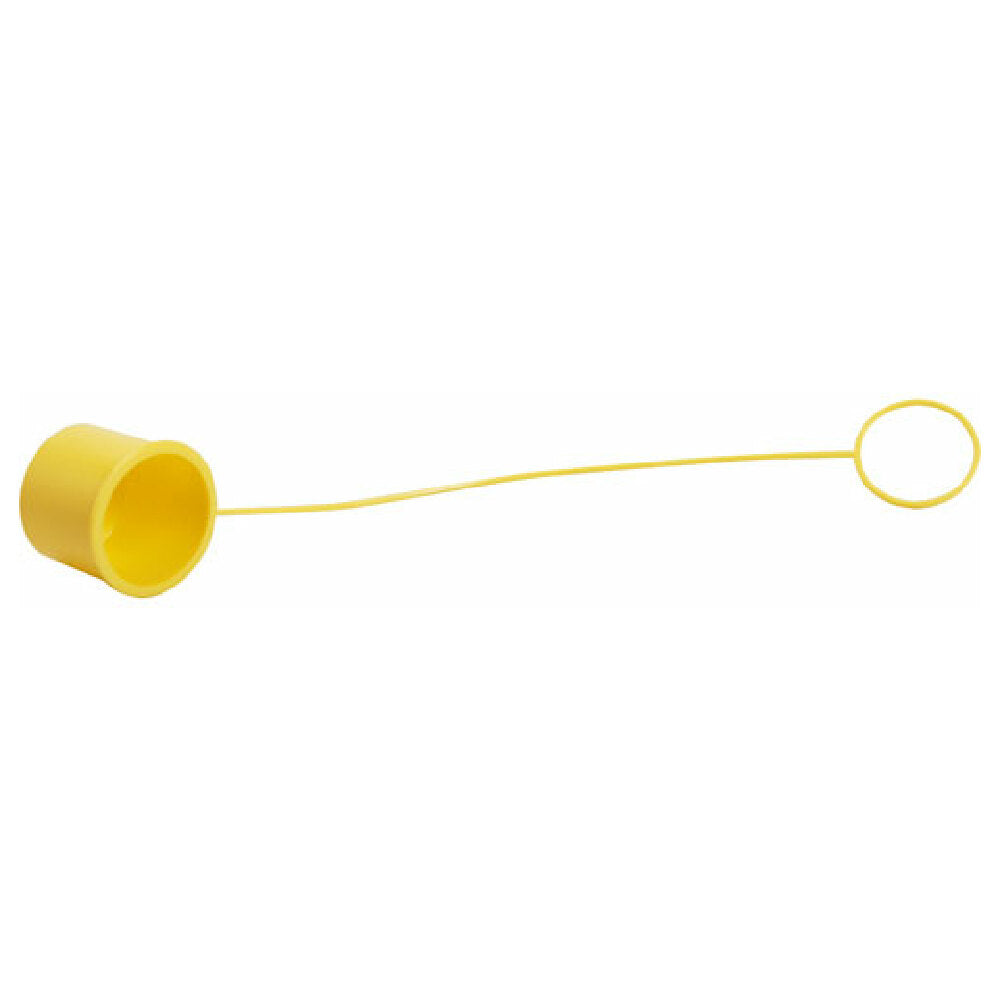

AllPoints BDY107-371 6 Inch Cap Dust Eye Wash Station Plastic Yellow

- Durable plastic construction resists chemicals and wear.

- Bright yellow color enhances safety visibility instantly.

- Precisely 6-inch length ensures optimal emergency coverage.

- View More Details

Best Price Guarantee

Best Price Guarantee

Secure Shopping

Secure Shopping

The Bradley BDY107-371 Cap Dust Eye Wash Station is a commercial safety device designed for emergency eyewash applications in food processing, laboratory, or industrial facilities. Manufactured by Bradley, this eye wash station features a durable plastic construction, with a vibrant yellow color to ensure high visibility. Measuring 6 inches (152 mm) in length with an outer diameter of 1/16 inch (2 mm), it is engineered for ease of installation and maintenance. This eyewash component is specifically designed to meet safety standards for rapid personnel response, providing a reliable solution for eye contamination incidents in various high-risk industrial environments. Its technical specification emphasizes compatibility with standard eye wash stations, enabling seamless integration into safety setups requiring specific tubing or cap dust protections.

The firmware of the AllPoints BDY107-371 Cap Dust Eye Wash Station includes a 6-inch plastic tube with a 1/16-inch outer diameter, optimized for emergency eyewash coverage. Crafted from high-quality plastic, it offers excellent durability under frequent use and exposure to cleaning agents. Its bright yellow color enhances visibility in safety zones, facilitating quick access during emergencies. The design ensures straightforward installation, with dimensions suited for various safety equipment configurations. It is suitable for environments demanding reliable eye wash mechanisms with minimal maintenance and rapid response capability.

Ideal for safety stations in industrial or food production facilities, ensuring reliable eye wash response during emergencies.

The Bradley BDY107-371 Cap Dust Eye Wash Station features a 6-inch plastic body with a bright yellow finish, optimized for emergency safety applications in commercial environments. It is constructed from high-grade plastic, ensuring resistance to chemical agents commonly used in industrial settings. The outer diameter of 1/16 inch (2 mm) allows seamless compatibility with standard tubing and fittings. Weighing just 0.01 lbs, this lightweight component is designed for easy installation and replacement access. It operates within typical safety fixture tolerances without requiring electrical connections, emphasizing its role as a passive safety device. The component's precise dimensions and durable material make it suitable for use in environments demanding quick, reliable responses to eye contamination incidents. Its straightforward design facilitates regular cleaning without disassembly, ensuring ongoing functionality.

A commercial eye wash station is a safety fixture designed to provide immediate decontamination for the eyes following exposure to hazardous substances, chemicals, or debris. The Bradley BDY107-371 Cap Dust Eye Wash Station, with its 6-inch plastic tubing and bright yellow color, is installed as part of emergency safety systems in industrial and food processing environments. It is typically positioned in areas where eye contamination risk is high and is used to deliver rapid flushing action to mitigate injury. Its sturdy construction and standard sizing make it suitable for quick replacement and integration into existing safety protocols, serving critical roles in maintaining health and safety in high-risk workplaces.

Secure, reliable safety components like the AllPoints BDY107-371 are essential in industrial safety protocols for rapid eye decontamination, suited for medium-workload safety stations in foodservice, manufacturing, or laboratory settings. The product by AllPoints offers durable, easy-to-maintain eye wash solutions with precise dimensions and robust materials designed for continuous operation during emergency responses.

The AllPoints BDY107-371 Cap Dust Eye Wash Station differs from standard components through its lightweight design, high durability, and high-visibility finish, ensuring quick accessibility and reliable emergency response. Its simple installation process and compatibility with existing safety fittings make it a practical choice for busy industrial or foodservice environments. This model enhances operational safety through robust construction and minimized maintenance needs, contributing to compliance with safety standards and response readiness in hazardous workplaces.