AllPoints 107-371 1.25 Inch Yellow Plastic Eye Wash Station with Cap Dust

- Footprint and configuration support compact setups

- Capacity handles high throughput demands efficiently

- Core specs enable reliable emergency response

- View More Details

Best Price Guarantee

Best Price Guarantee

Secure Shopping

Secure Shopping

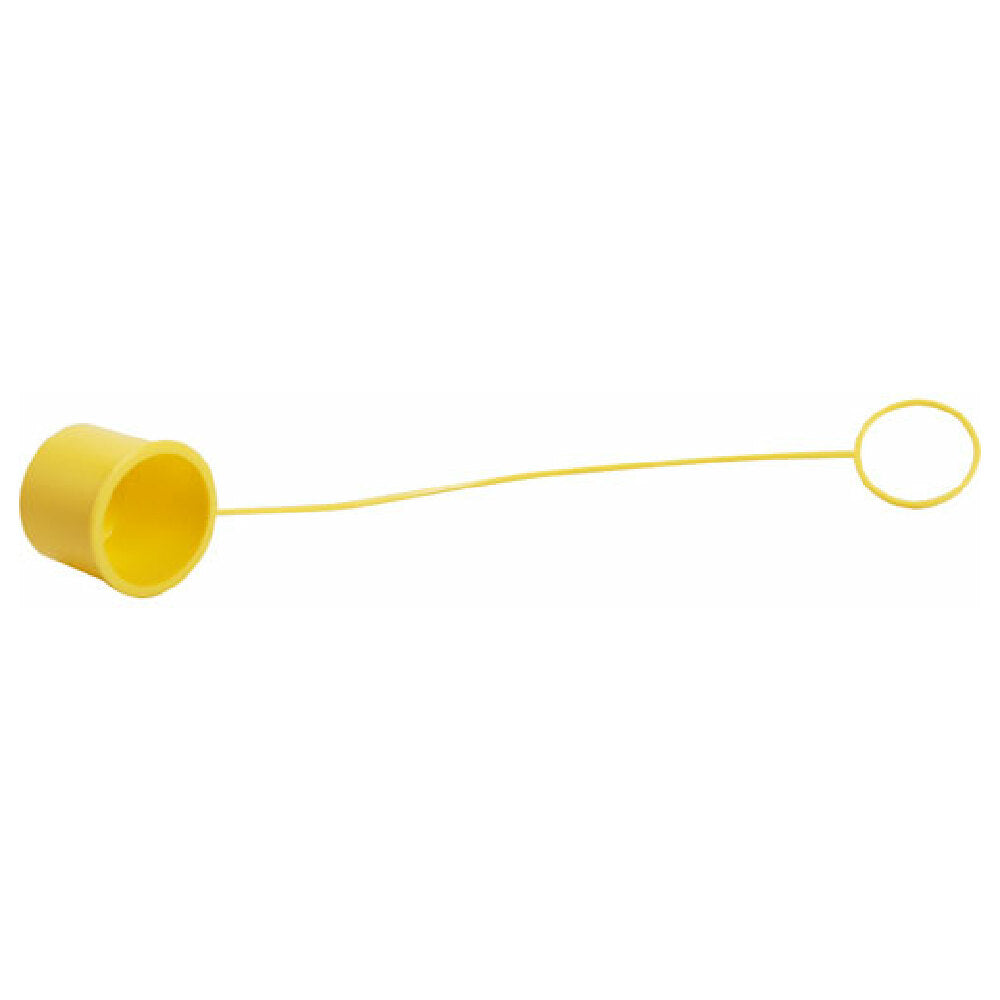

The Bradley 107-371 Cap Dust Eye Wash Station, manufactured by AllPoints and available as part of their professional-grade safety equipment, is designed for emergency eye irrigation in industrial and commercial environments. Constructed from durable plastic and finished in bright yellow for high visibility, this eye wash station features a 6-inch (152 mm) long cap with an outer diameter of 1/16 inch (2 mm), ensuring reliable operation in safety-critical settings. Its compact dimensions and robust material make it suitable for installation in food processing plants, manufacturing facilities, and laboratory environments where quick access to eye wash stations is essential. The model’s precise specifications facilitate easy integration into safety protocols for workplace hazard mitigation and employee protection. Its technical details support quick and effective eye irrigation, essential for compliance and safety management in commercial foodservice and industrial operations.

The AllPoints 107-371 Cap Dust Eye Wash Station offers specialized function for emergency eye irrigation, featuring a durable plastic construction tailored for high-use industrial environments. Its compact size enables easy installation in tight spaces, with a 6-inch (152 mm) length ensuring accessible, reliable operation. Designed for durability, the yellow finish enhances visibility and safety compliance, while low-maintenance parts simplify routine checks and repairs. Ideal for use in food manufacturing, laboratories, and industrial kitchens, it supports swift response to eye hazards, streamlining safety workflows for commercial operators.

Designed for organizations requiring quick, reliable eye wash access in safety-critical areas.

The AllPoints 107-371 Cap Dust Eye Wash Station features a straightforward, compact design with dimensions of 1.25 inches (width) by 8.5 inches (depth) and a height of 1 inch. Its lightweight construction weighs only 0.01 lbs, simplifying installation. Made from high-quality plastics suitable for demanding environments, it maintains its integrity under typical workplace temperatures. Its bright yellow exterior ensures high visibility, promoting safety adherence. The device is engineered for quick deployment, with a 6-inch length cap that features a 1/16 inch outer diameter and a 2 mm opening, enabling prompt eye irrigation during emergencies. No electrical requirements or cooling/ refrigeration components are included, aligning with its intended function as a manual safety accessory. The product's design supports straightforward maintenance and inspection routines, making it ideal for placement in industrial kitchens, manufacturing zones, and laboratory safety stations.

A commercial eye wash station is a safety device designed to provide immediate eye irrigation to mitigate chemical, dust, or debris hazards in industrial and foodservice environments. The AllPoints Bradley 107-371 Cap Dust Eye Wash Station is a portable, manually operated unit that offers quick access during emergencies, installed in workplaces like manufacturing floors, laboratories, or commercial kitchens. Its robust plastic construction and bright yellow finish ensure durability and visibility, supporting compliance and rapid response. Specifically designed to deliver a precise flow of water through a 6-inch cap with a 1/16 inch opening, it facilitates efficient eye flushing, making it an essential component of workplace safety protocols in environments prone to eye hazards and chemical splashes, especially in medium-usage industrial settings.

Designed for industrial safety, the AllPoints Bradley 107-371 provides reliable emergency eye irrigation with a robust plastic build, ideal for medium-volume manufacturing, food processing, and laboratory environments requiring quick safety responses. AllPoints 107-371 ensures effective hazard mitigation in commercial kitchen equipment and safety stations through its compact, durable construction and precise operation.

Compared to standard eye wash stations, the Bradley 107-371 stands out due to its durable plastic construction, bright safety yellow finish, and precise 6-inch cap with a 1/16 inch opening. Its compact form factor allows for versatile installation in tight workspaces, enhancing safety logistical workflows. The unit’s high visibility and low-maintenance design improve operational efficiency and adherence to safety standards, making it a reliable choice for industrial and foodservice environments that prioritize worker protection and hazard response readiness.