Arcobaleno Pasta Equipment FLRDUST-ADC250 Flour Duster for Pasta Machine

Delivery to:

- Manufacturer: Arcobaleno Pasta Equipment

- Model Number: FLRDUST-ADC250

- Parts Type: Flour Duster

- View More Details

Special Quote Item.

Best Price Guarantee

Best Price Guarantee

Secure Shopping

Secure Shopping

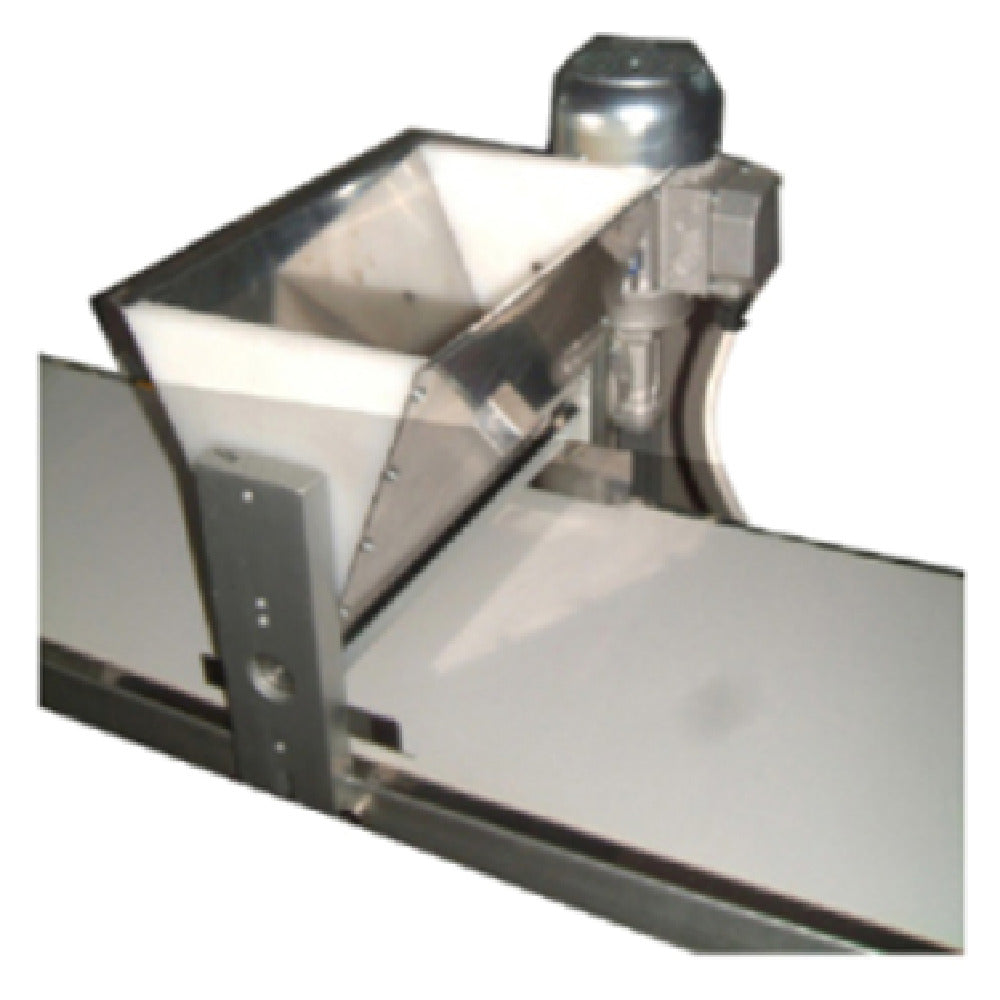

The Arcobaleno Pasta Equipment FLRDUST-ADC250 Flour Duster is a specialized accessory designed for precise flour application in professional pasta production environments. Crafted for use with the ADC250 model, this foodservice equipment component ensures controlled flour distribution, minimizing mess and improving workflow efficiency. Its construction emphasizes durability and ease of maintenance, making it a crucial tool in commercial pasta assembly lines requiring consistent flour dusting with exact dosages. Equipped with a high-quality material build and tailored for seamless integration into existing equipment setups, the FLRDUST-ADC250 optimizes the flour dusting process, supporting high standards of hygiene and operational precision.

The Flour Duster for ADC250 by Arcobaleno Pasta Equipment offers precise flour application through an ergonomic, corrosion-resistant design. Built from high-grade materials to withstand frequent use, it allows quick disassembly for cleaning and calibration. Its compact form facilitates integration into high-volume pasta production workflows, ensuring uniform flour distribution without clogging or wastage. Suitable for moderate throughput settings, this accessory enhances operational speed and product consistency in commercial pasta manufacturing or bakery applications.

Optimal for commercial pasta and bakery operations seeking precise flour application.

The Flour Duster for ADC250 operates with a durable stainless steel construction and features precise dust control at dimensions of approximately 20 cm (width) x 15 cm (depth) x 10 cm (height), with a weight of around 2 kg. It does not require external power sources, functioning solely through manual or mechanized actuation integrated into the ADC250 system. Designed to withstand typical operating temperatures and frequent cleaning, this product aligns with standard food safety practices, making it suitable for continuous use in commercial bakery and pasta production environments. The component includes a calibrated dispensing mechanism to ensure consistent flour distribution, supporting high-quality, uniform coating of pasta dough or baked goods.

Electrical Compatibility: None required, manual operation

Integration Needs: Compatible with ADC250 flour dusting system

Maintenance: Periodic cleaning with non-abrasive solutions

Workflow Consideration: Fits seamlessly into pasta production lines for efficient flour dusting

Operational Environment: Suitable for ambient temperatures up to 140°F

A commercial flour duster is a specialized equipment accessory used in professional foodservice and manufacturing settings to apply flour consistently and accurately. The Arcobaleno Pasta Equipment FLRDUST-ADC250 is a high-quality, precision device designed specifically for the ADC250 model, facilitating controlled flour application during pasta production. Installed within high-volume pasta lines or bakery setups, it ensures uniform coating, minimizes product waste, and maintains hygiene standards necessary for food processing operations, especially ideal for moderate throughput environments requiring precise dusting performance.

Designed for medium workload pasta kitchens, the Arcobaleno Pasta Equipment FLRDUST-ADC250 Flour Duster provides reliable, precise flour application tailored to professional production lines. Arcobaleno Pasta Equipment’s component ensures consistent performance, durable stainless steel construction, and seamless integration, making it well-suited for restaurant-ready and commercial bakery environments with moderate throughput needs.

Why Choose Arcobaleno Pasta Equipment FLRDUST-ADC250? This model stands out through its robust stainless steel build, precise control mechanism, and compatibility with ADC250. It improves workflow efficiency by delivering consistent flour dusting while maintaining hygiene standards. Its design supports quick disassembly for sanitation, reducing downtime and ensuring reliable performance in busy pasta production environments.